Selective pallet racking

Selective Pallet Raking Systems from a Top Pallet-Racking Supplier

Engineered Slective Rack Systems with 100% Direct Pallet Access

Speak with an expert ![]() 515-635-1555

515-635-1555

Home / Selective Pallet Racking Systems

As an experienced selective pallet-racking supplier and integrator, Midwest Warehouse Solutions partners with UNARCO—the oldest pallet rack manufacturer in the United States—to design, supply, and install selective pallet racking systems for real-world warehouse operations. We provide end-to-end solutions, including engineering, product selection, and installation, supported by one of the industry’s broadest selective racking portfolios and built to meet ANSI, OSHA, and application-specific requirements.

Our selective racking systems include teardrop racking, narrow aisle pallet racking, galvanised pallet racking, and specialty solutions such as painting rack systems, all engineered to meet ANSI, OSHA, and industry-specific requirements.

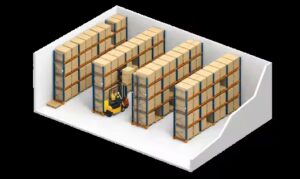

What is Selective Pallet Racking?

Selective pallet racking is a warehouse storage system that stores pallets one deep, providing 100% direct forklift access and a high degree of layout flexibility. Because every pallet can be accessed without moving others, it is the most commonly deployed pallet-racking solution in modern warehouses.

Often referred to as selective rack or selective racking system, this configuration is widely used across distribution, manufacturing, and logistics operations where SKU variety, accessibility, and adaptability are critical.

In practice, selective pallet racking is typically chosen when warehouse operations require:

- High SKU accesibility

Including environtments with large or diverse SKU counts. - Accurate invetory control

Especially for slow to moderate inventory turnover. - Operation flexibility

Allowing layouts to be adjusted as storage needs evolve. - FIFO inventory rotation

Suporting compliance and efficient order fulfillment.

From an operational standpoint, selective pallet racking is considered the baseline pallet-racking system because it balances accessibility, simplicity, and scalability better than higher-density alternatives.

Key Features & Benefits of

Selective Pallet Racking

Selective pallet racking remains the most commonly recommended system by warehouse engineers and pallet-racking manufacturers because it balances performance, flexibility, and cost better than any alternative.

Why we recommend Selective Pallet Racking at Midwest Warehouse Solutions:

100% Selectivity

Every pallet is always accessible

Lowest cost per pallet position

Ideal for cost-controlled operation

Highly flexible layout

Easily adapts to changing SKUs or inventory flow

Compatible with narrow aisle racking

Increasees density without sacrificing access.

Available in teardrop and structural designs

Matches load and environment requirements

Galvanised pallet racking options

Extends lifespan in corrosive or cold environments

FIFO-friendly

Simplifies inventory rotation and compliance

Expandable and easily reconfigurable over time

Supports warehouse growth, layout changes, and evolving pallet storage requirements without requiring a full racking system replacement.

How a Selective Racking System Works

A standard selective racking system is built around a modular steel structure that supports pallets at adjustable heights.

A typical selective pallet racking system consists of:

- Teardrop uprights or structural uprights

- Horizontal load beams

- Optional wire decking or pallet supports

In teardrop racking, beams connect to the teardrop upright using a boltless, teardrop-shaped connector. This design allows for fast installation, easy beam height adjustment, and future reconfiguration with minimal downtime.

For heavier pallet loads or harsher environments, structural selective racking uses fully bolted steel components, offering increased durability and impact resistance.

Key Variations Within Selective Pallet Racking

Teardrop Racking vs Structural Selective Racking

Both systems fall under the selective pallet racking category, but they serve different operational needs.

|

|

Feature | Structural Selective Racking | Teardrop Racking (Roll-formed) |

|---|---|---|

| Upright type | Structural steel upright | Teardrop upright |

| Beam connection | Fully bolted | Boltless |

| Installation speed | Slower | Faster |

| Initial cost | Higher | Lower |

| Best use | Cold storage, heavy loads | Standard warehouse |

| Aisle compatibility | Standard or narrow aisle | Standard or narrow aisle |

Structural Selective Racking

Feature

| Upright type | Structural steel upright |

| Beam connection | Fully bolted |

| Installation speed | Slower |

| Initial cost | Higher |

| Best use | Cold storage, heavy loads |

| Aisle compatibility | Standard or narrow aisle |

Teardrop Racking (Roll-formed)

Feature

| Upright type | Teardrop upright |

| Beam connection | Boltless |

| Installation speed | Faster |

| Initial cost | Lower |

| Best use | Standard warehouse |

| Aisle compatibility | Standard or narrow aisle |

Selective Pallet

Racking for Narrow

Aisle Warehouses

Narrow aisle racking and narrow aisle pallet racking configurations use selective rack systems designed to operate with:

- Reach trucks

- Turret trucks

- Articulated forklifts

By reducing aisle width while maintaining direct pallet access, narrow aisle selective pallet racking significantly increases storage density without sacrificing selectivity.

This makes narrow aisle pallet racking ideal for:

- High real-estate-cost warehouses

- Distribution centers maximizing cubic space

- Operations requiring bith density and flexibility

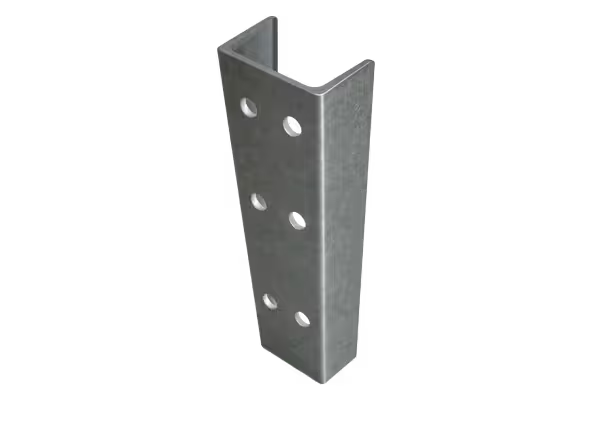

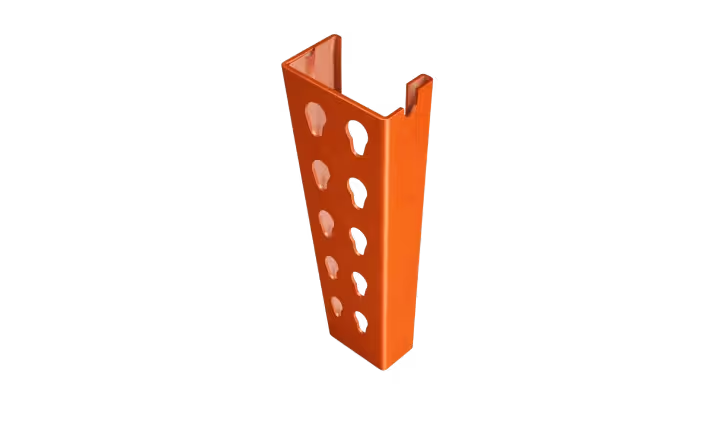

Galvanised Pallet Racking Applications

Galvanised pallet racking uses zinc-coated steel components to resist corrosion and moisture.

Common applications include:

- Cold storage and freezer warehouses

- Food & beverage facilities

- Wash-down environments

- Outdoor or semi-exposed storage areas

Galvanised selective pallet racking maintains the same structural design as standard systems while offering extended lifespan in harsh conditions.

Custom Built Racks

Custom built racks are engineered selective pallet racking solutions designed to meet specific operational, spatial, and workflow requirements that standard pallet racking configurations cannot address.

While they are based on selective pallet racking components, custom rack systems are modified or purpose-built to support non-standard products, unique room layouts, specialized storage functions, or integrated workstations.

These systems are commonly used in:

- Manufacturing facilities

- Sign shops and fabrication environments

- Maintenance and tool storage areas

- Warehouses with mixed-use storage and work zones

Below are two real-world examples of how selective pallet racking can be custom engineered to solve specific storage and operational challenges.

Example 1

Selective Rack with Vertical Dividers for Sign Storage

This custom selective pallet rack was designed for a sign manufacturing shop requiring organized storage of large-format signage while maintaining additional selective pallet positions.

Key features include:

- Vertical dividers for safe, upright sign storage

- Two additional selective rack levels for palletized materials

- Custom bay widths and heights to match sign dimensions

- Layout engineered to fit the customer’s room size and workflow

This system was built around the customer’s:

- SKU count and invetory turnover

- Physical space constraints

- Handling requirements and future growth expextations

The result is a highly selective, space-efficient rack system that supports both flat product storage and traditional pallet storage within the same structure.

Example 2

Custom Selective Rack Workbench & Tool Storage System

This custom-built system uses a single row of selective pallet racking, 24 inches deep, consisting of three 8-foot sections designed to function as a combined workbench, tool storage, and general storage solution.

Key features include:

- Steel workbench top integrated into the rack structure

- Industrial steel pegboard with hooks for tool organization

- Built-in electrical outlets and task lighting

- Two remaining rack sections equiped with wire decking for tote and hand-loaded box storage

This solution transforms standard selective pallet racking into a multi-functional industrial workstation, ideal for:

- Maintenance departments

- Fabrication shops

- Assembly and repair areas

Which Pallet Racking System

Is Right for My Warehouse?

|

|

|

|

Buyer question | Selective Pallet Racking | Push-Back Racking | Pallet Flow Racking | Drive-In / Drive-Thru |

|---|---|---|---|---|

| Can I access every pallet directly? | Yes – 100% access | Partial | No | Partial |

| Is this best for many SKUs? | Excellent | Moderate | Poor | Moderate |

| Is this the most flexible system? | Yes | Limited | No | No |

| Works with FIFO inventory? | Yes | Sometimes | No | Yes |

| Compatible with narrow aisle forklifts? | Yes | No | No | No |

| Lowest upfront cost per pallet? | Yes | Higher | Medium | Highest |

| Easy to reconfigure or expand later? | Very easy | Difficult | No | No |

| Most common system recommended by manufacturers? | Yes | No | No | No |

| Best choice for long-term scalability? | Yes | Limited | No | No |

Selective Pallet Racking

Buyer Questions

| Can I access every pallet directly? | Yes – 100% access |

| Is this best for many SKUs? | Excellent |

| Is this the most flexible system? | Yes |

| Works with FIFO inventory? | Yes |

| Compatible with narrow aisle forklifts? | Yes |

| Lowest upfront cost per pallet? | Yes |

| Easy to reconfigure or expand later? | Very easy |

| Most common system recommended by manufacturers? | Yes |

| Best choice for long-term scalability? | Yes |

Push/Back Racking

Buyer Questions

| Can I access every pallet directly? | Partial |

| Is this best for many SKUs? | Moderate |

| Is this the most flexible system? | Limited |

| Works with FIFO inventory? | Sometimes |

| Compatible with narrow aisle forklifts? | No |

| Lowest upfront cost per pallet? | Higher |

| Easy to reconfigure or expand later? | Difficult |

| Most common system recommended by manufacturers? | No |

| Best choice for long-term scalability? | Limited |

Pallet Flow Racking

Buyer Questions

| Can I access every pallet directly? | No |

| Is this best for many SKUs? | Poor |

| Is this the most flexible system? | No |

| Works with FIFO inventory? | No |

| Compatible with narrow aisle forklifts? | No |

| Lowest upfront cost per pallet? | Medium |

| Easy to reconfigure or expand later? | No |

| Most common system recommended by manufacturers? | No |

| Best choice for long-term scalability? | No |

Drive-In / Drive Thru

Buyer Questions

| Can I access every pallet directly? | Partial |

| Is this best for many SKUs? | Moderate |

| Is this the most flexible system? | No |

| Works with FIFO inventory? | Yes |

| Compatible with narrow aisle forklifts? | No |

| Lowest upfront cost per pallet? | Highest |

| Easy to reconfigure or expand later? | No |

| Most common system recommended by manufacturers? | No |

| Best choice for long-term scalability? | No |

Why Selective Pallet Racking Is the Default Choice for Most Warehouses

Across most warehouse operations, decision-makers prioritize direct pallet access, SKU flexibility, operational simplicity, cost control, and future scalability. When evaluated against these criteria, selective pallet racking consistently outperforms alternative racking systems.

Unlike high-density systems that restrict access or limit reconfiguration, selective pallet racking provides 100% selectivity, supports FIFO inventory rotation, and works seamlessly in both standard and narrow aisle pallet racking layouts. This makes it especially effective for warehouses handling many SKUs, fluctuating inventory levels, or evolving operational requirements.

From a manufacturer and engineering perspective, selective racking is also the lowest-risk and most adaptable pallet racking system. Beam levels can be adjusted, aisles can be reconfigured, and systems can be expanded without major structural changes, which is why top pallet-racking manufacturers.

Why Choose Midwest Warehouse Solutions as Your Pallet-Racking Supplier

Many companies sell pallet racking. Fewer operate as a true pallet-racking supplier and integrator.

As a top pallet-racking integrator, Midwest Warehouse Solutions provides:

- Manufacturer-engineered selective pallet racking systems.

- Expertise in teardrop racking, narrow aisle pallet racking, and galvanised pallet racking.

- In-house warehose consulting, design, racking engineering, installation, inspection, and reconfiguration.

- ANSI MH16.1 and OSHA-compliant designs.

- Long-term support across the Midwest and United States.

Selective Pallet Racking

Systems FAQ’S

What is selective pallet racking and why is it so commonly used?

Selective pallet racking is a pallet storage system that stores pallets one deep, providing 100% direct access to every pallet. It is the most commonly used racking system because it offers the best balance of accessibility, flexibility, cost, and scalability for most warehouses.

Is selective pallet racking the best option for warehouses with many SKUs?

Yes. Selective pallet racking is widely considered the best option for warehouses with many SKUs because every pallet can be accessed directly without moving others, making inventory management and order picking more efficient.

Can selective pallet racking be used in narrow aisle warehouses?

Yes. Selective pallet racking is commonly used in narrow aisle pallet racking configurations with reach trucks, turret trucks, or articulated forklifts, allowing higher storage density without sacrificing pallet access.

What is the difference between teardrop racking and structural selective racking?

Teardrop racking uses boltless beam connections for fast installation and easy adjustability, making it ideal for standard warehouse environments. Structural selective racking uses fully bolted steel components and is better suited for heavy loads, cold storage, or harsher operating conditions.

Is galvanized pallet racking necessary for cold storage or food facilities?

Galvanized pallet racking is recommended for cold storage, food and beverage facilities, wash-down environments, and any application where corrosion resistance is required. It extends system lifespan while maintaining the same structural design as standard selective racking.

Is MWS a pallet-racking manufacturer or a supplier?

MWS operates as a full-service pallet racking supplier and integrator, providing engineered, turn-key storage solutions tailored to each warehouse’s pallet storage needs and growth objectives.

We design optimal racking layouts, perform load calculations, ensure code compliance, and manage complete turn-key sales and installation services for warehouses of any size or location. Rather than simply reselling standard rack components, we deliver fully integrated pallet racking systems designed for performance, safety, and long-term scalability.

Why do top pallet-racking suppliers recommend selective pallet racking as a default solution?

Top pallet-racking suppliers and warehouse engineers often recommend selective pallet racking because it is the most flexible, lowest-risk system. It supports FIFO inventory, adapts easily to change, and can be expanded or reconfigured without major structural modifications.

CLAIM YOUR

FREE

Consultation

Save Time and Money

Request a Custom Selective Pallet Racking Quote

Whether you operate a growing distribution center, a manufacturing facility, or a warehouse with evolving inventory needs, working with a top pallet-racking supplier and integrator ensures your selective racking system performs reliably today and scales efficiently tomorrow.

Speak to a warehouse racking expert

515-635-1555

Save time. We will contact you

Provide your details, and we’ll help you find exactly what you need