Optimize warehouse space with MWS’s storage mezzanine solutions. We understand the value of every square foot in the facility, and our experts are here to help you make the most of it. However, our team has the experience to design and install mezzanines tailored to your needs. Our teams actively raise space to maximize functionality with hydraulic pallet jack. We understand the significance of every square foot in your facility, and our experienced team is here to help you unlock its full potential. However, we’re actively elevating space to ensure maximum functionality and mezzanine lift.

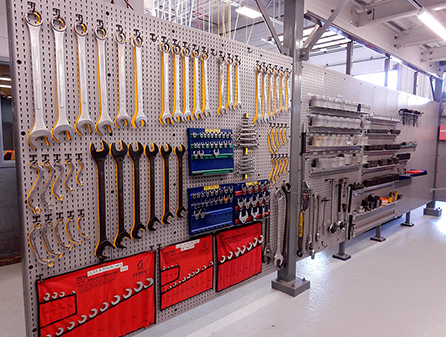

At MWS, we specialize in providing storage mezzanine. We know one size doesn’t fit all, so our team works closely with you to understand unique requirements. Whether pallet racking, shelving systems, or a combination of both. We design, deliver, and install storage solutions that enhance warehouse efficiency. Choose MWS for the flexibility, quality, and expertise you need for storage space in a dynamic productivity hub.

We understand that a one-size-fits-all approach doesn’t work. So, we collaborate closely with you to grasp your distinct requirements. Our installed storage solutions are designed to actively boost shelving supported mezzanine warehouse’s efficiency. However, select for MWS to experience flexibility, quality, and expertise. All the requirements are for turning storage mezzanine into a dynamic productivity center.

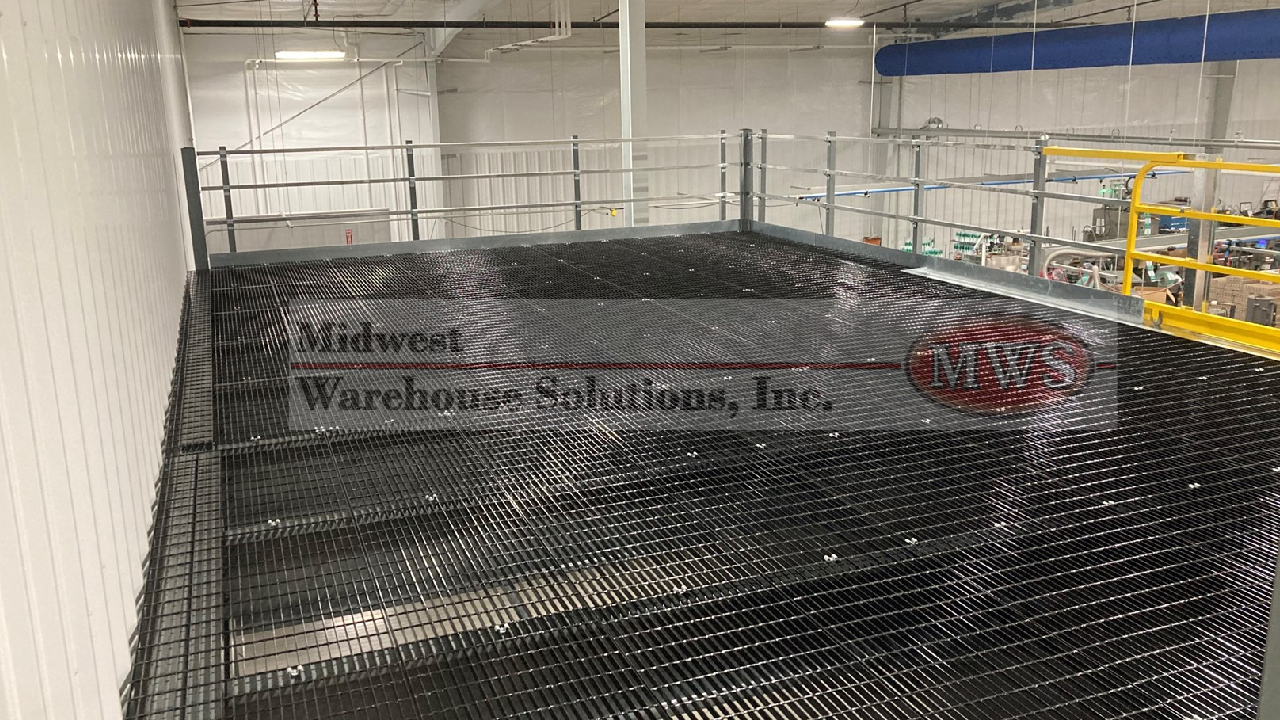

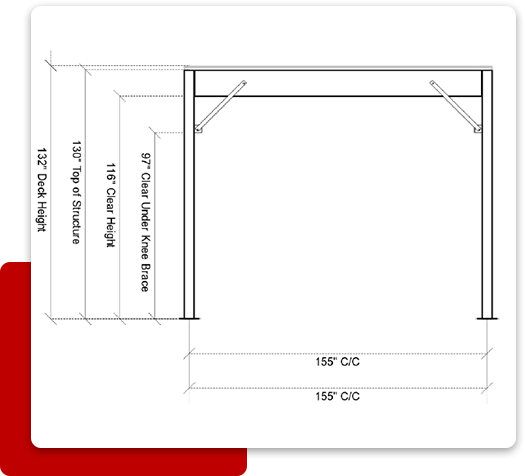

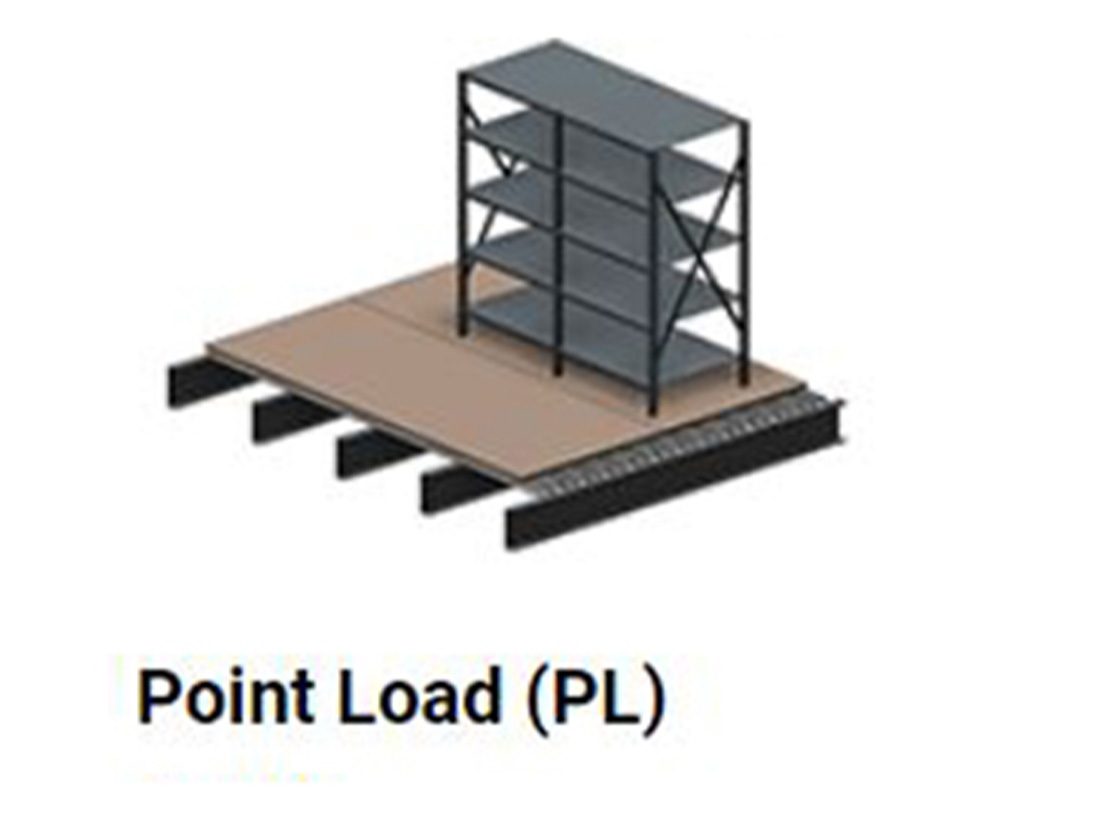

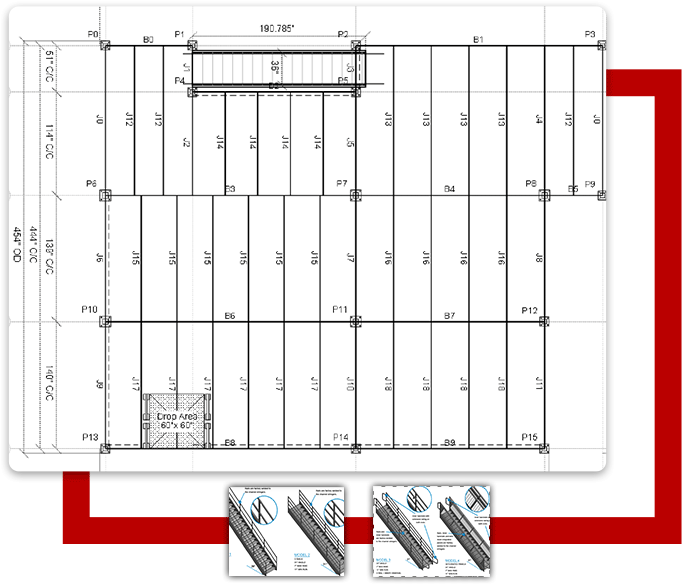

Single Level Work platforms will increase storage capacity, minimize construction costs & install quickly. Moreover, single Level Work Platforms or “Mezzanines” are fully engineered to fit your Uniformly Distributed Load, Point Load or Pallet Jack Load. Our team will review your project and provide the most cost effective Solution to increase Storage & Productivity.

Design & Review of: Mezzanine Load Capacity, Flooring Options, Stairs, Gates, Handrails, Engineering, Quoting, Delivery & Installation.

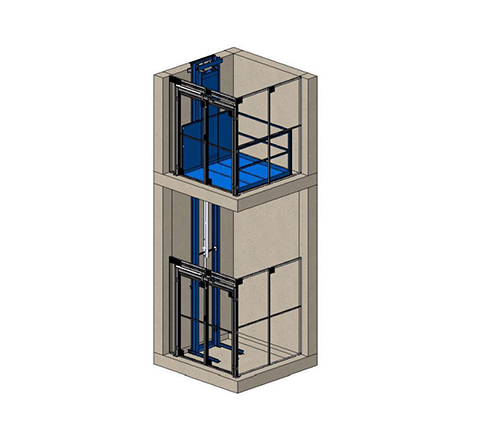

For Warehouse Facilities that have much taller clear ceiling heights available, Free Standing Two Level Mezzanines can be Engineered for both Storage and Distribution Facilities.

Start with understanding the following:

Length _______ ?

Width ________ ?

Top of Deck Height ______?

Clear Height _________?

UDL _____? (Heaviest Pallet to be Stored)

PL ______ ? (Shelving Load L x W x H x how many shelves per section)

PJL _____ ? (Heaviest Pallet to be Stored we will calculate pallet jack use)

4 Options to choose from:

Solid Surface Board Plain or Grey Finish _______ ?

Open Flooring Bar-Grating ____________ ?

Diamond Grip Flooring ______?

Corrugated Decking Ready for Concrete _________?

Concrete

Thickness 4”

Corrugated Decking

Standard Width 3'-0"

Standard Length

4',8',9',10',11',12',13',14',15',16'

Diamond Grip Flooring

Standard Width 6',9",12"

Standard Length

12'

Open Bar Grating

Standar width 3’-0’’ standard length 4’,8, 12’, 16’,20’,24’

Rasin Board

Standard Sheet Size

4'x 8'/32 sq ft

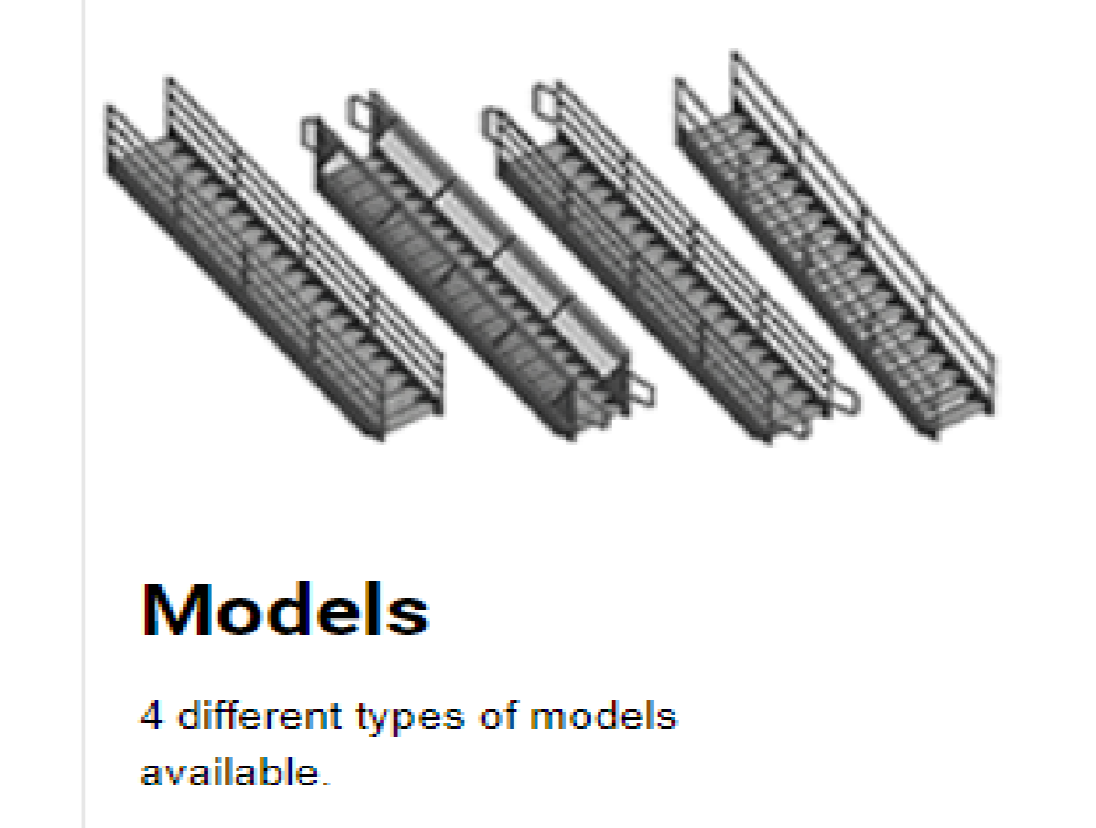

4 Options of Stairs to Choose From:

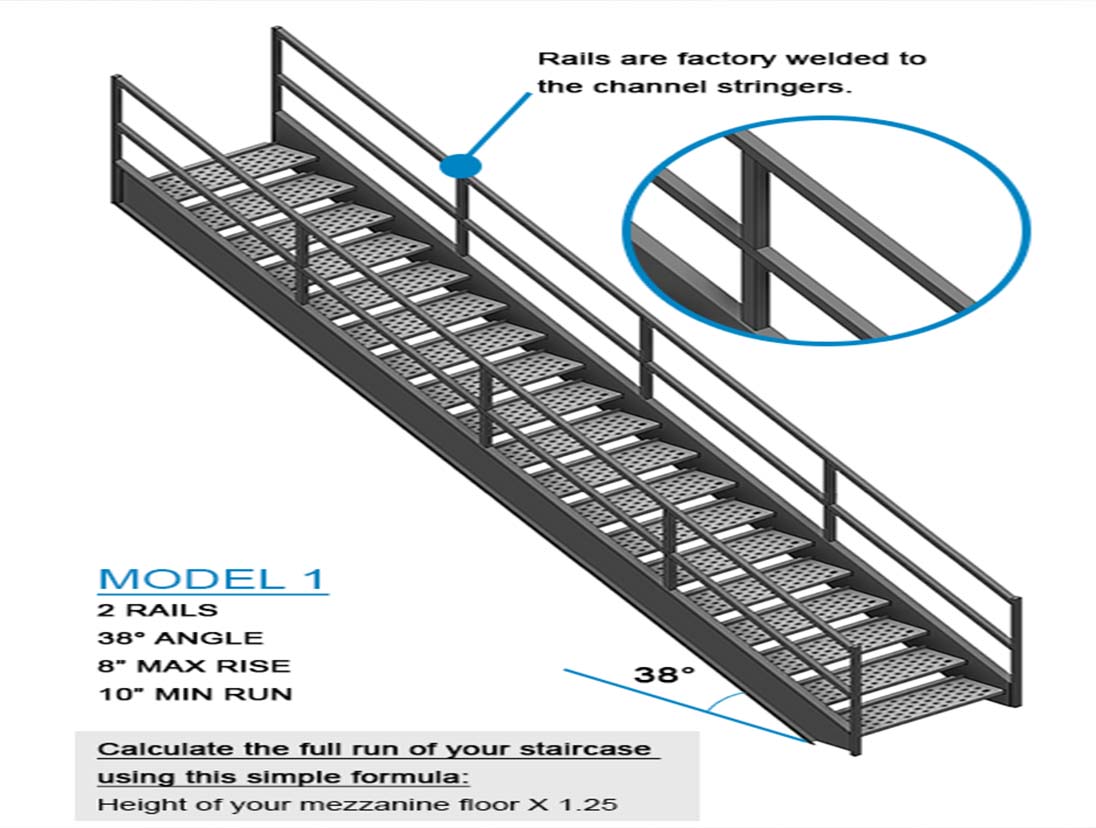

Model 1 ________ ? (2 Rails, 38* Angle, 8″ Max Rise , 10″ Min Run)

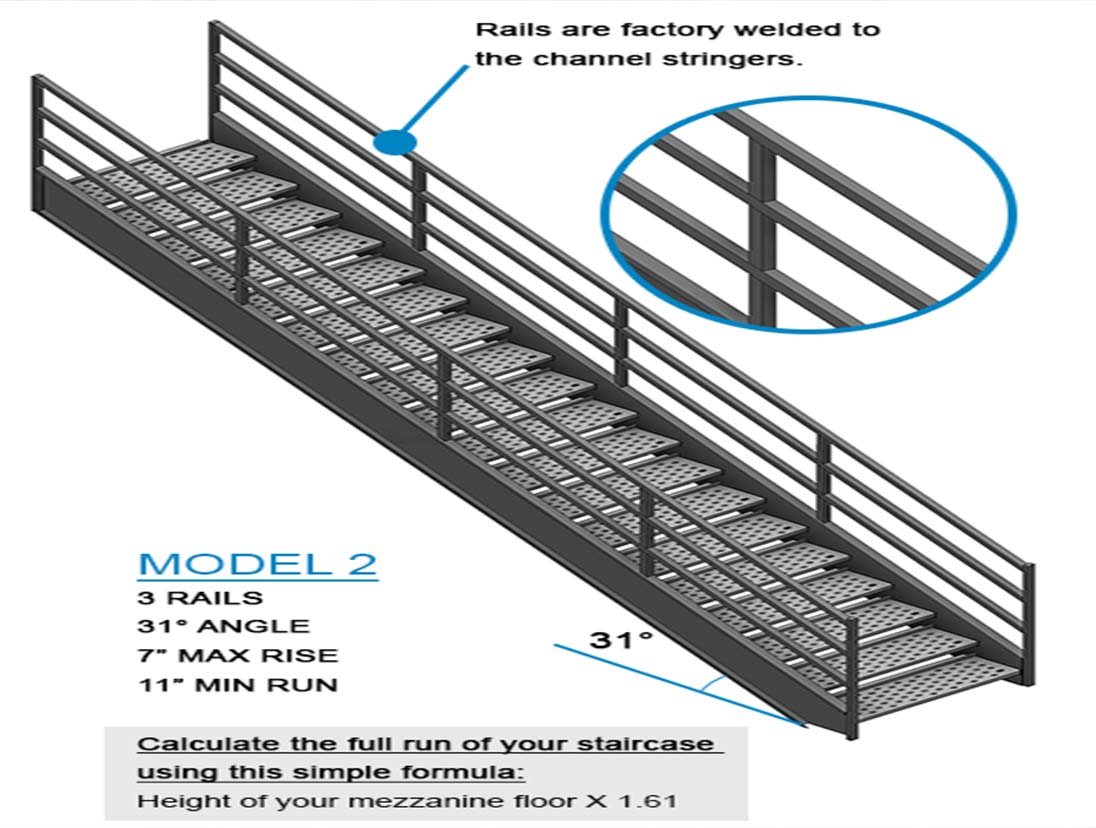

Model 2 ________ ? (3 Rails, 31* Angle, 7″ Max Rise, 11″ Min Run)

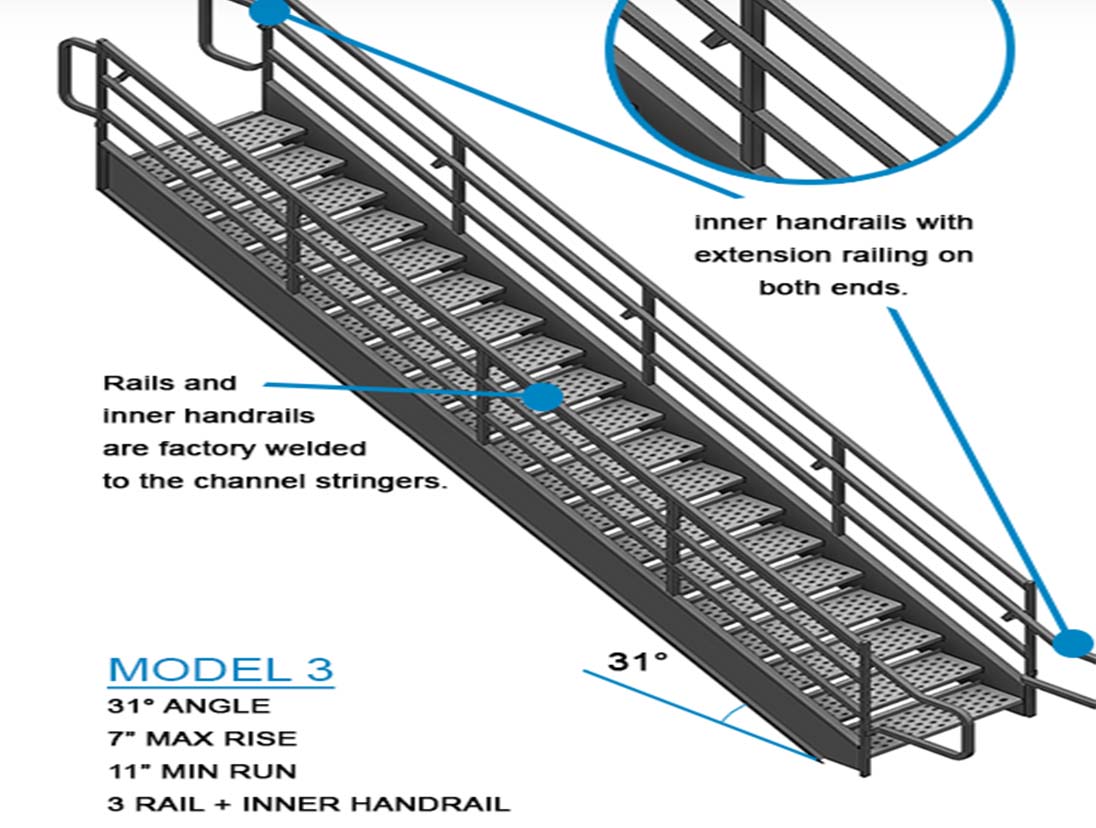

Model 3 ________ ? (3 Rails + Inner Handrail & 31* Angle)

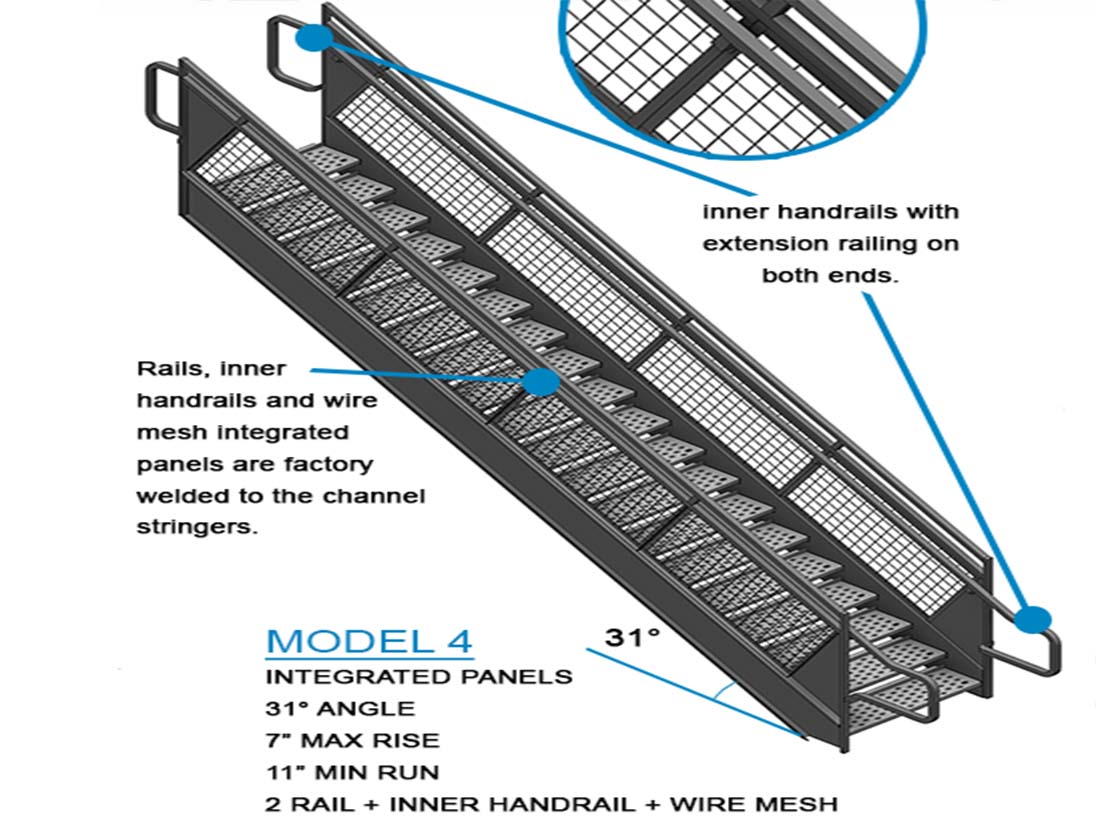

Model 4 ________ ? (2 Rails + Inner Handrail + Wire Mesh, 7″ Max Rise, 11″ Min Run)

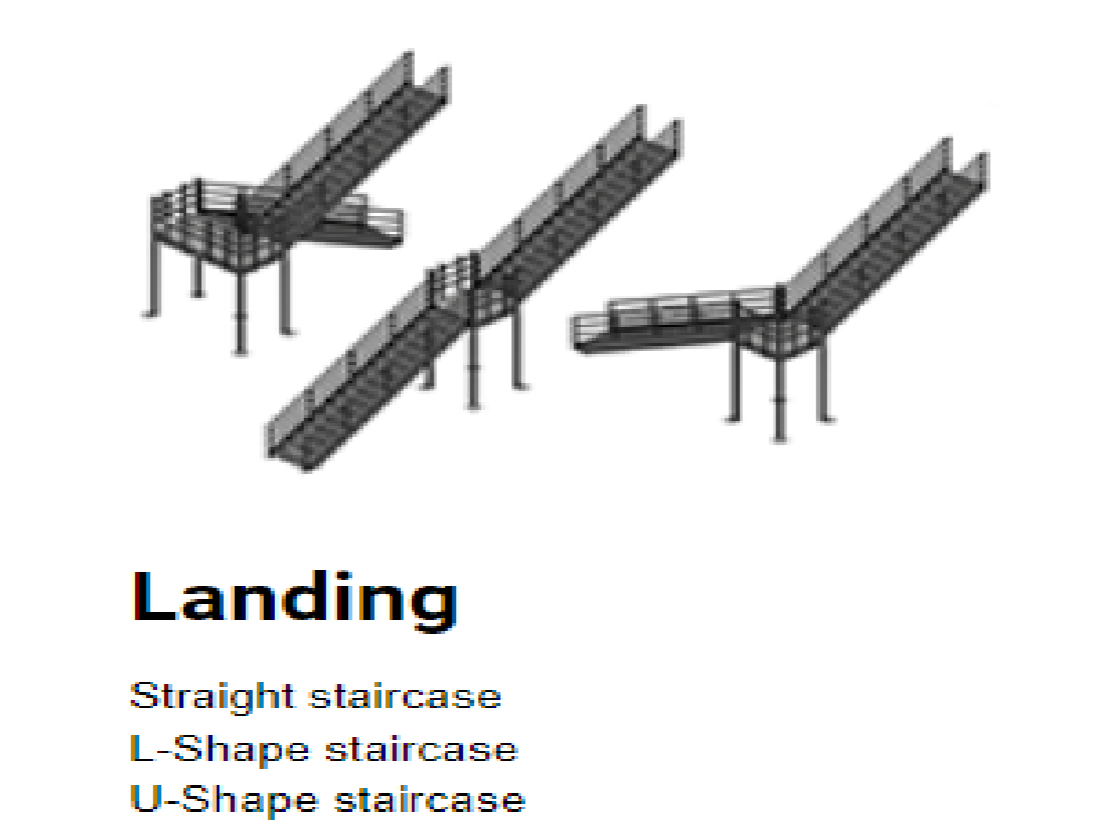

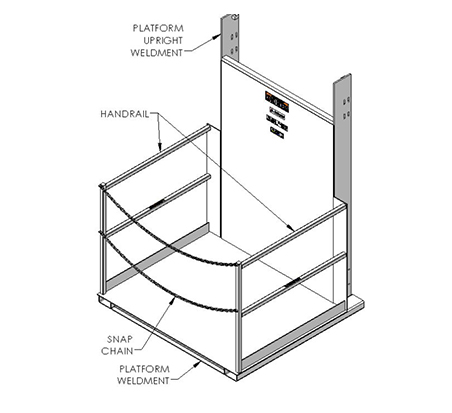

3 Options to Consider:

2 Rail _______ ?

3 Rail ________ ?

Wire Mesh Handrail ______?

Choose a Gate:

Single Swing _________ ?

Double Swing ________?

Sliding _______________?

Lift Out ______________?

Pivot Gate ___________?

Safety Pivot

Standard Gate Width

5’, 6’, 7’, 8’, 9’, 10’, 11’, 12’, 13’,

Single Swing

Standard Width Opening

2’6’’ , 3’, 3’6’’, 4

Sliding Gate

Standard Width Opening

5’, 6’, 7’, 8’, 10’, 12’

Lift-out Safety Gates

Standard Width Opening

4’,5’

MWS & Cogan will generate approval drawings so all options quoted can be reviewed onsite with Customer’s Signature Acceptance Required.

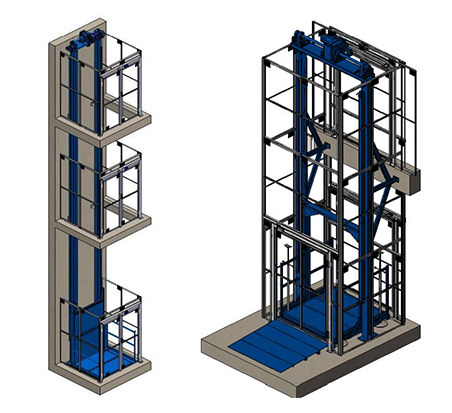

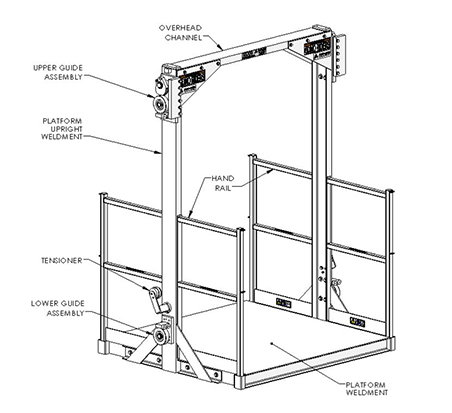

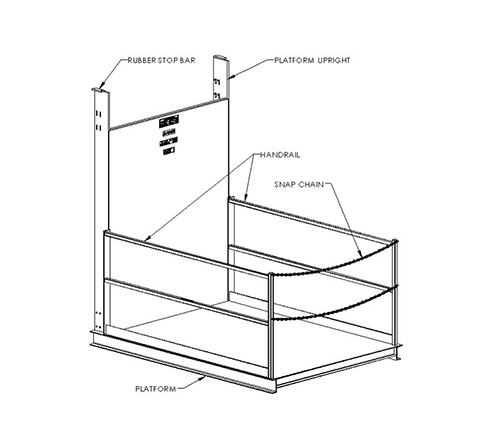

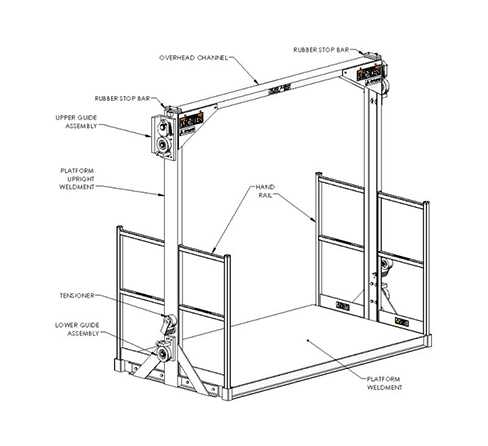

Mechanical VRC Lifts

Standard mechanical cantilever

-Lift capacity up to 5,000 lbs.

High Load” mechanical cantilever

-Lift capacity up to 10,000 lbs.

Platform sizes

-Up to 12 ft wide x 8 ft long

“C”, “Z” or 90-degree loading patterns

Freestanding models available with an optional support structure

Allows material movement with the smallest possible equipment footprint

May be used where headroom is restricted

Provides extra flexibility to maneuver loads

Modular multi-level systems

Variable frequency drive system providing “soft-start”, and “soft-stop” to cushion loads

Full height enclosures available

A single-stop unit can be fully-assembled, tested, and ready to operate

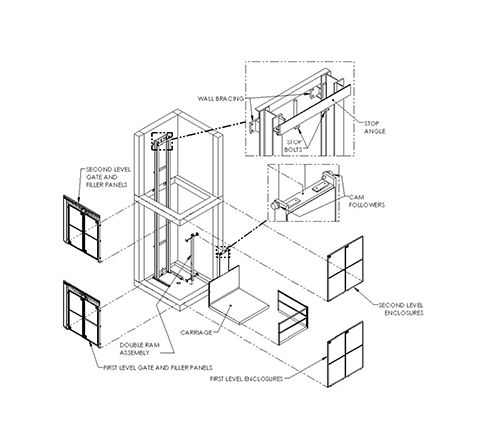

Hydraulic VRC Lifts

Lift Capacity

Lift Capacity

Lifting Height

up to 28 ft.

Lifting Speed

24 FPM

“Gate Closed” indicator light on the control panel

Momentary contact “Up” and “Down” push button controls

There are two hydraulic lift configurations – Straddle and Cantilever.

To choose the best one for your application you willneed to determine your necessary load capacity, frequency, and loading/unloading requirements.

Hydraulic VRC Lifts

Lift Capacity

Lift Capacity

Lifting Height

up to 28 ft.

Lifting Speed

24 FPM

“Gate Closed” indicator light on the control panel

Momentary contact “Up” and “Down” push button controls

There are two hydraulic lift configurations – Straddle and Cantilever.

To choose the best one for your application you willneed to determine your necessary load capacity, frequency, and loading/unloading requirements.

Mechanical VRC Lifts

Standard mechanical cantilever

-Lift capacity up to 5,000 lbs.

High Load” mechanical cantilever

-Lift capacity up to 10,000 lbs.

Platform sizes

-Up to 12 ft wide x 8 ft long

“C”, “Z” or 90-degree loading patterns

Freestanding models available with an optional support structure

Allows material movement with the smallest possible equipment footprint

May be used where headroom is restricted

Provides extra flexibility to maneuver loads

Modular multi-level systems

Variable frequency drive system providing “soft-start”, and “soft-stop” to cushion loads

Full height enclosures available

A single-stop unit can be fully-assembled, tested, and ready to operate

Options:

Options:

Material Handling Equipment Sales & Installations

contact info

CALL US 24/7

quick links

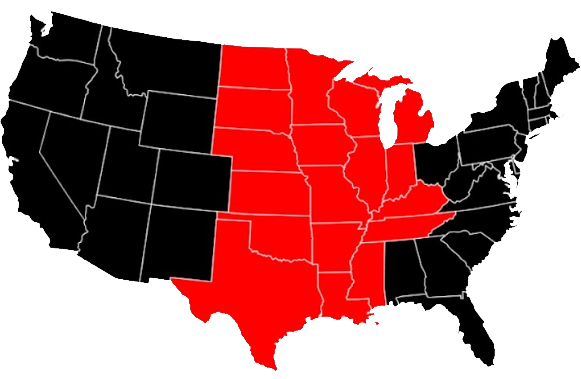

Proudly Serving The Midwest

Copyright 2024 All Rights Reserved. MWS