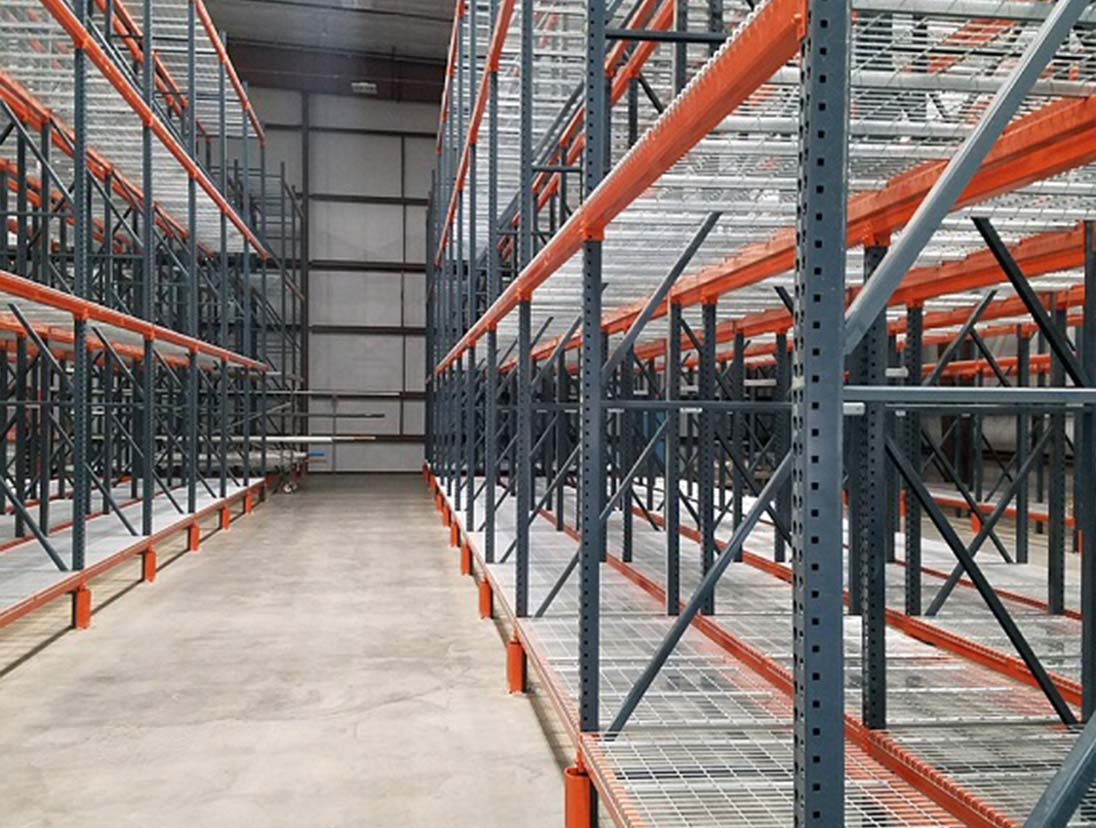

Empower your warehouse’s storage capabilities with MWS. Our experienced experts recognize that adequate storage is the cornerstone of a thriving warehouse operation. We merely install pallet rack system. Therefore, we actively optimize space, enhance safety, and streamline processes to boost efficiency. Trust MWS for top-tier quality. However, witness your warehouse evolve into a vibrant productivity hub.

Our seasoned experts understand that an efficient storage system is the foundation of a thriving warehouse operation. We offer warehouse racking installation to meet your specific needs, including selective, pushback, drive-in, and more. When you partner with us, we actively optimize your space, enhance safety, and streamline your operations for peak efficiency. Trust in MWS for excellence in quality, and pallet rack system transforms warehouse into a bustling hub of productivity

MWS has Stocking Inventory on hand in most popular sizes and capacities.

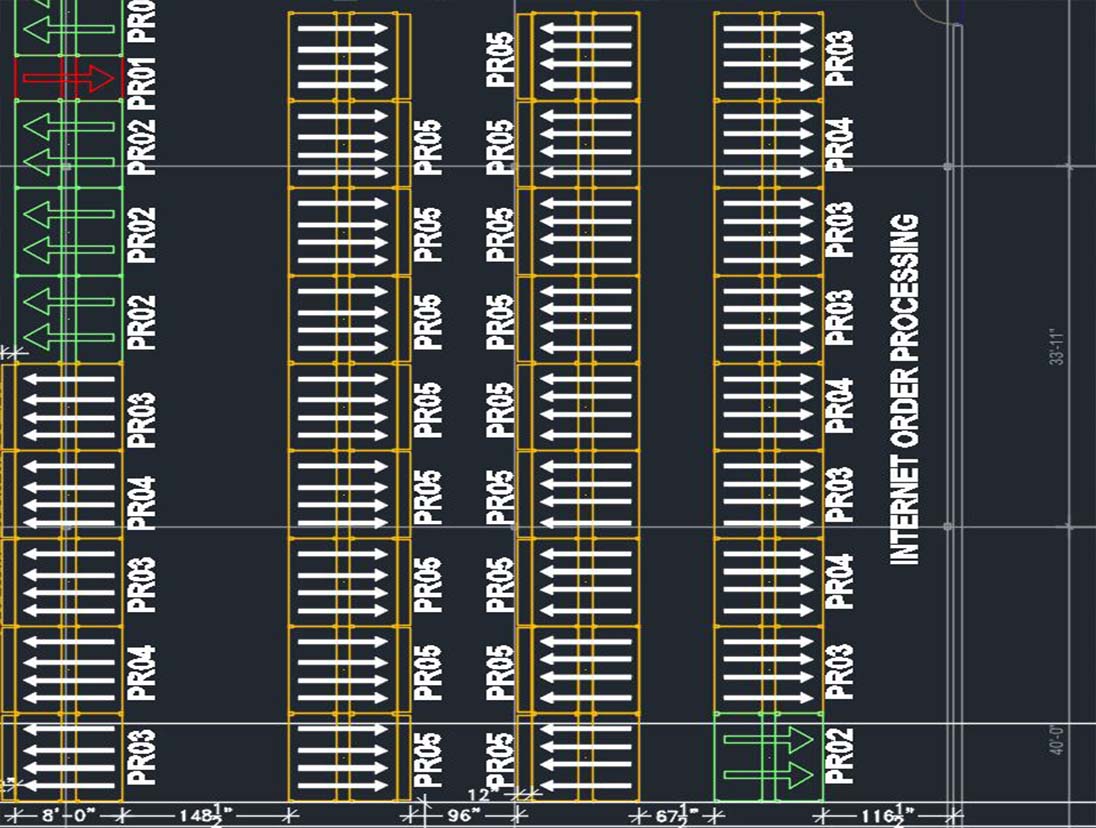

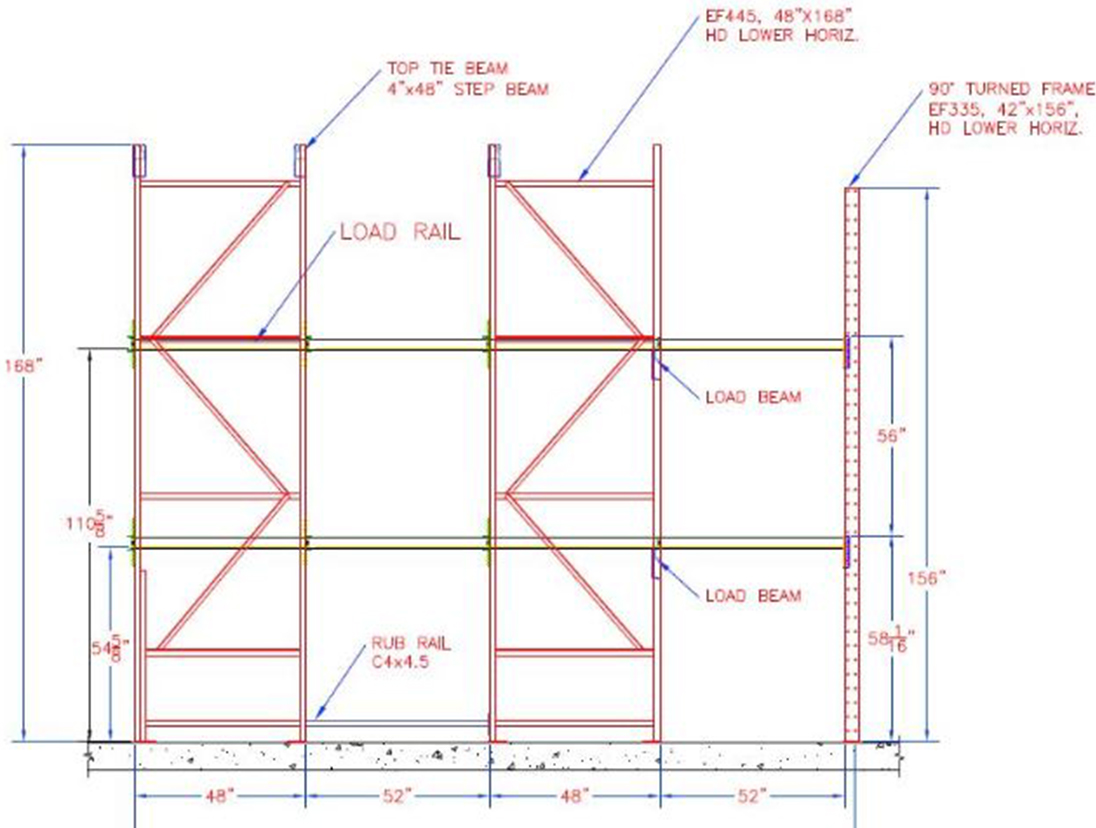

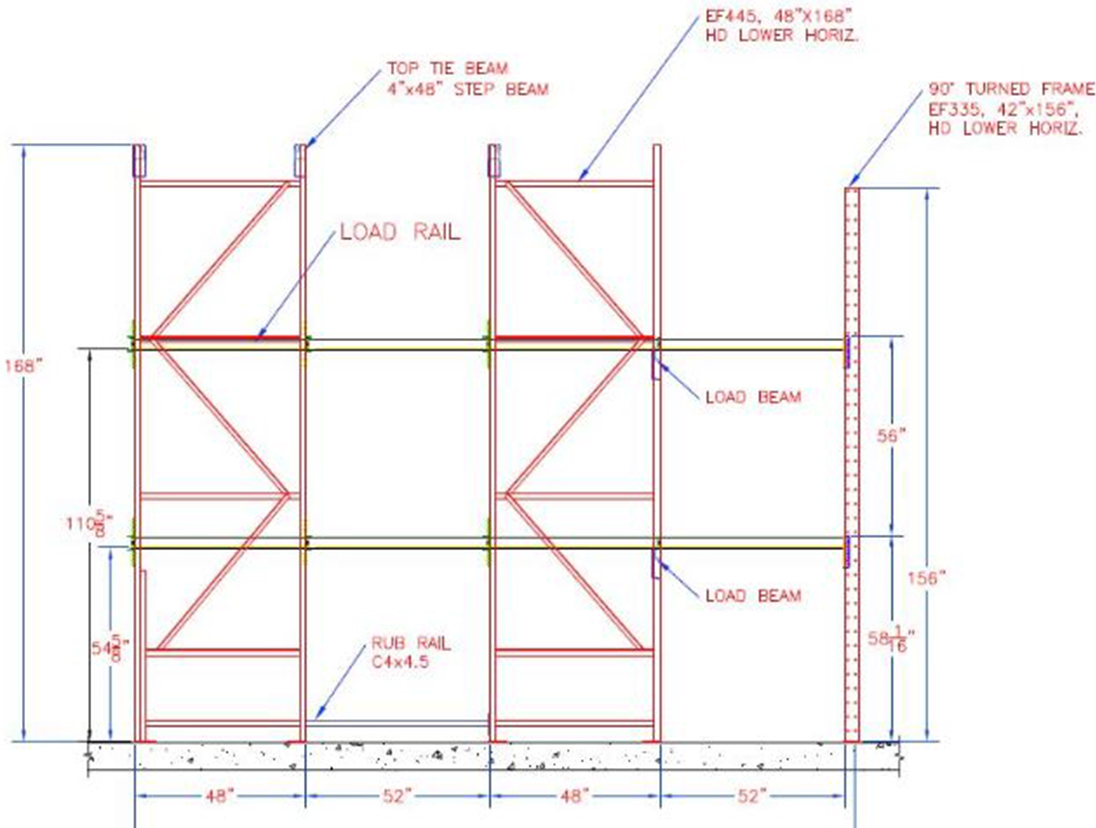

Drive In Systems: load and retrieve from the same entry point creating LIFO – Last-in-first-out condition. Pallets are stored end to end eliminating aisles for exceptional dense storage. We can design a system around the turn rate and product selectivity needs of your warehouse.

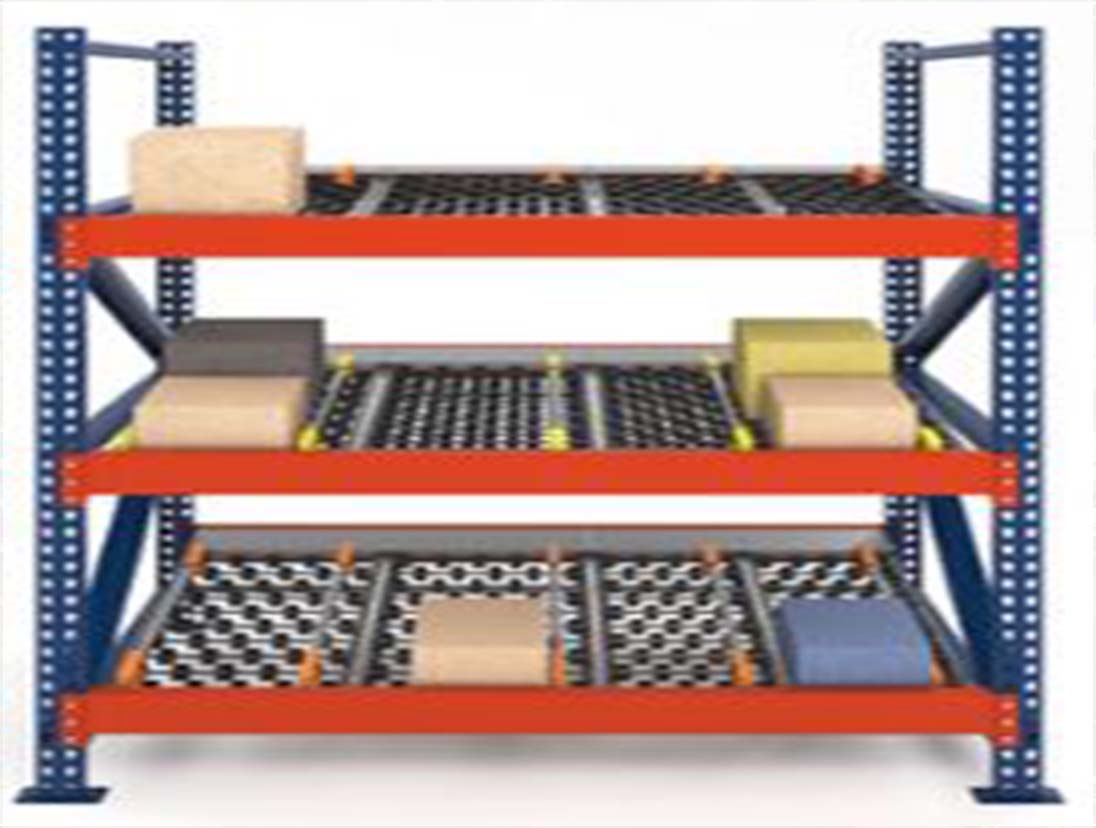

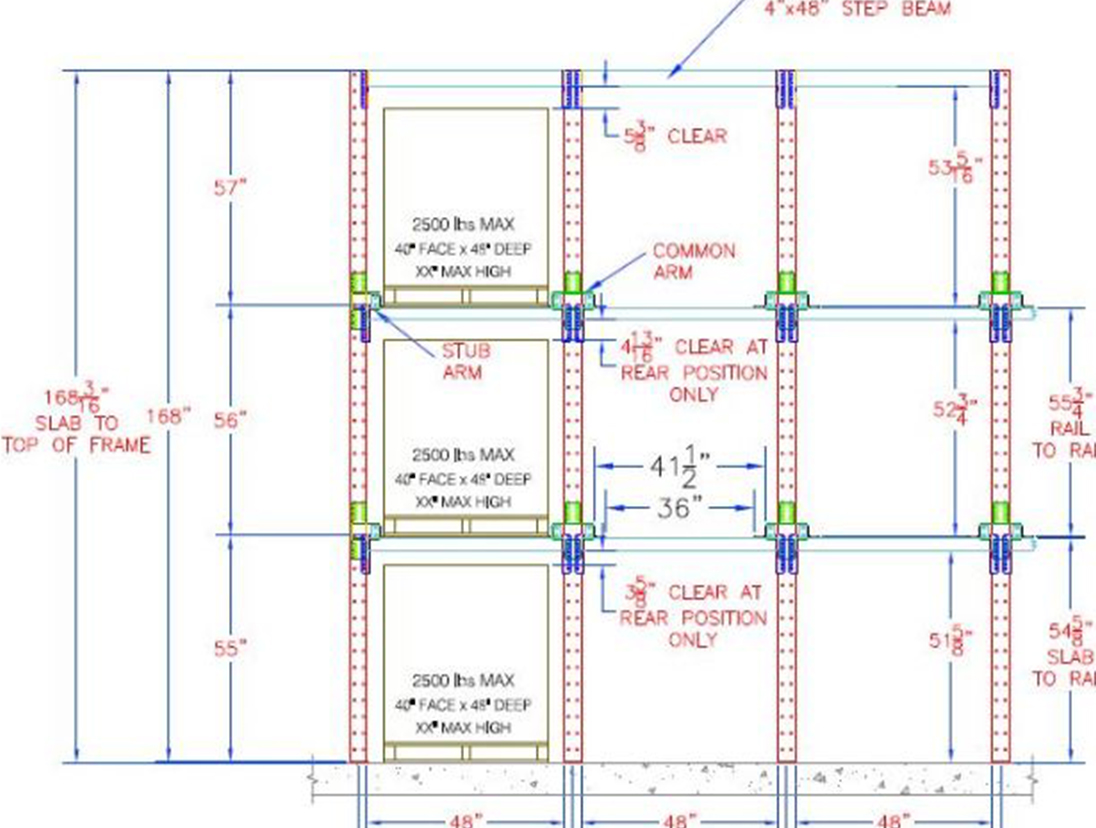

Fully modular, Rack Capacity is 25,000lbs. per section and 50,000lbs. per bay (seismic zones 1 and 2).

Pallets placed in 4″ vertical increments. Items can be stored just where you want them, and are positioned via positive engagement system.

Ergonomic handling. Unique handling device maneuvers on four axes, creating 360-degree flexibility-makes removing even large loads easy.

Simple, intuitive positioning. Enables the operator to relocate a pallet quickly, accurately, and safely (pallets are removed and replaced by guiding the mast to the new position ).

Easy-to-learn and easy-to-use controls. No license or certification required.

Material Handling Equipment Sales & Installations

contact info

CALL US 24/7

quick links

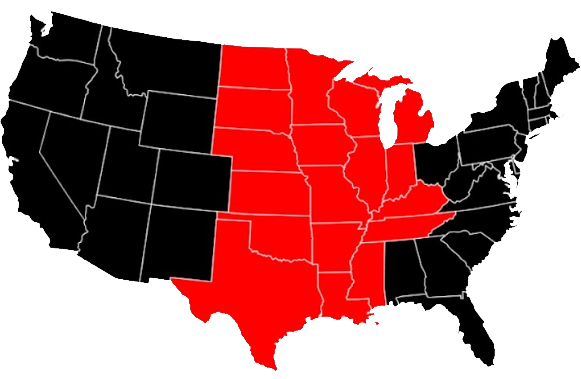

Proudly Serving The Midwest

Copyright 2024 All Rights Reserved. MWS