Cantilever racking

Cantilever Racking from a Top Warehouse Racking Supplier

Cantilever Racking from a Top Warehouse Racking Supplier

Speak with an expert ![]() 515-635-1555

515-635-1555

Home / Cantilever Racking Systems

Cantilever racking is the preferred warehouse storage solution for long, bulky, or irregular materials such as lumber, pipe, tubing, steel profiles, and sheet goods. As a cantilever racking supplier and integrator, we design and install cantilever racking systems that provide clear, unobstructed access while safely supporting heavy and oversized loads in real-world warehouse and yard environments.

Our cantilever warehouse racking systems are engineered to match actual load conditions, handling equipment, and operational workflows across manufacturing, distribution, and industrial facilities.

What Is Cantilever Racking?

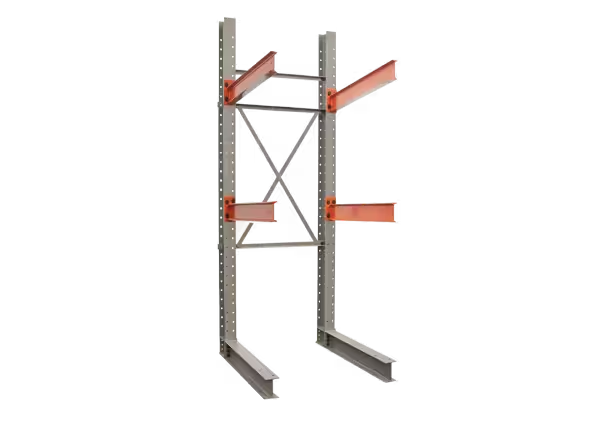

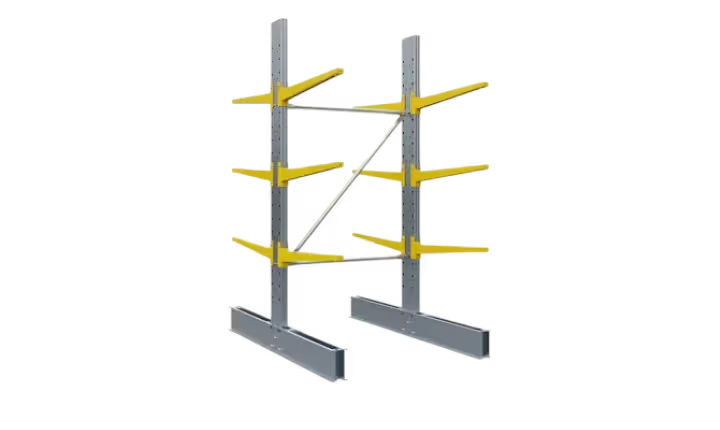

Cantilever racking is a warehouse storage system designed to store long, bulky, or oversized materials using horizontal cantilever rack arms that extend from vertical steel columns. Because the system has no front uprights, materials of varying lengths can be loaded and retrieved without obstruction.

Often referred to as cantilever pallet racking, cantilever storage rack, or cantilever racking system, this solution is used when materials cannot be safely or efficiently stored on pallets or within standard pallet rack bays.

From an operational perspective, cantilever racking is most often selected when storage requirements are driven by material length, shape, or overhang, rather than pallet quantity. In practice, it is commonly used for materials such as lumber, pipe, tubing, steel profiles, and bundled goods, where clear access and flexible handling are essential.

For these applications, cantilever racking is widely considered the baseline storage system for long and bulky materials, offering a practical balance between accessibility, load support, and adaptability.

Key Features & Benefits of

Cantilever Pallet Racking

Once long or oversized materials are part of daily operations, the performance of the storage system depends on how efficiently materials can be handled, supported, and accessed without disruption. Cantilever racking is designed to address these operational requirements directly.

Why we recommend Cantilever Racking at Midwest Warehouse Solutions:

Open-front storage design

Enables fast, unobstructed loading and unloading, reducing handling time and operator repositioning.

Heavy duty cantilever rack arms

Provide stable support for uneven or concentrated loads, minimizing material deflection and damage.

Steel cantilever rack construction

Delivers long-term durability in high-use or industrial environments.

Single sided or double sided configurations

Allows layouts to be optimized along walls or within central aisles.

Adjustable arm heights and spacing

Accommodates changes in material size, bundle height, or product mix over time.

Clear floor access

Works efficiently with forklifts, side loaders, and overhead cranes.

Expandable cantilever racking system

Supports future growth without requiring a complete system replacement.

This combination of features allows cantilever racking systems to improve handling efficiency, reduce material damage, and adapt to changing operational demands.

How a Cantilever Racking System Works

A standard cantilever racking system consists of:

- Vertical steel columns

- Horizontal cantilever rack arms

- Base plates anchored to the slab

- Optional bracing and decking (depending on use)

Materials are stored directly on the arms, which extend outward from the column. Because there are no front uprights, operators can load and unload materials of varying lengths without interference.

In practice, we design cantilever warehouse racking systems by accounting for:

- Load weight per arm

- Material lenght and distribution

- Handling method (forklift, crane, side loader)

- Indoor vs outdoor exposure

Key Variations Within

Cantilever Racking Systems

Single-Sided vs Double-Sided Cantilever Racking

Both configurations fall under the cantilever racking category, but they are typically selected based on available space, material volume, and access requirements.

|

|

Feature | Single-Sided Cantilever Rack | Double-Sided Cantilever Rack |

|---|---|---|

| Mounting | Against wall or edge | Freestanding |

| Storage access | One side | Both sides |

| Space efficiency | Good | Excellent |

| Typical use | Narrow spaces | High-volume storage |

Single-Sided Cantilever Rack

Feature

| Mounting | Against |

| Storage access | One side |

| Space efficiency | Good |

| Typical use | Narrow spaces |

Double-Sided Cantilever Rack

Feature

| Mounting | Freestanding |

| Storage access | Both sides |

| Space efficiency | Excellent |

| Typical use | High-volume storage |

Single sided cantilever rack systems are often used along warehouse walls, while double-sided systems maximize storage density in open floor layouts.

Types of Cantilever Racking Systems

Cantilever racking systems can be configured in several ways depending on material type, load weight, storage volume, and handling method. While all cantilever systems share the same open-front design, specific configurations are optimized for different operational requirements.

Below are the most common cantilever racking configurations we design and install, each tailored to a specific type of material or load condition.

01

Heavy Duty Cantilever Racking Systems

Heavy-duty cantilever racking systems are engineered for high-capacity loads, frequent handling, or demanding environments where standard cantilever configurations may not provide sufficient structural support. These systems use reinforced steel columns and heavy-duty cantilever rack arms to safely support dense bundles, heavy steel products, or large quantities of material. They are often specified for outdoor storage, high-impact environments, or operations with continuous material movement.

We typically recommend heavy-duty cantilever racking for facilities such as:

- Steel fabrication and processing facilities

- Industrial yards and outdoors storage areas

- Operations handling dense or high-weigh materials

where load capacity, durability, and long-term structural performance are essential.

02

Cantilever Racks for Lumber & Wood Products

Cantilever racks for lumber and wood products are among the most common cantilever racking applications. These systems are designed to support bundled boards, panels, and engineered wood of varying lengths while maintaining clear, unobstructed access to each load.

The open-arm design helps prevent edge and surface damage, allows for easy visual inspection of inventory, and makes it possible to access individual bundles without shifting or rehandling adjacent material. This improves both handling efficiency and material protection in day-to-day operations.

We commonly design cantilever wood rack systems for facilities such as:

- Lumber yards

- Building material suppliers

- Wood product manufacturers

where material turnover, visibility, and handling efficiency are critical to maintaining workflow and inventory control.

03

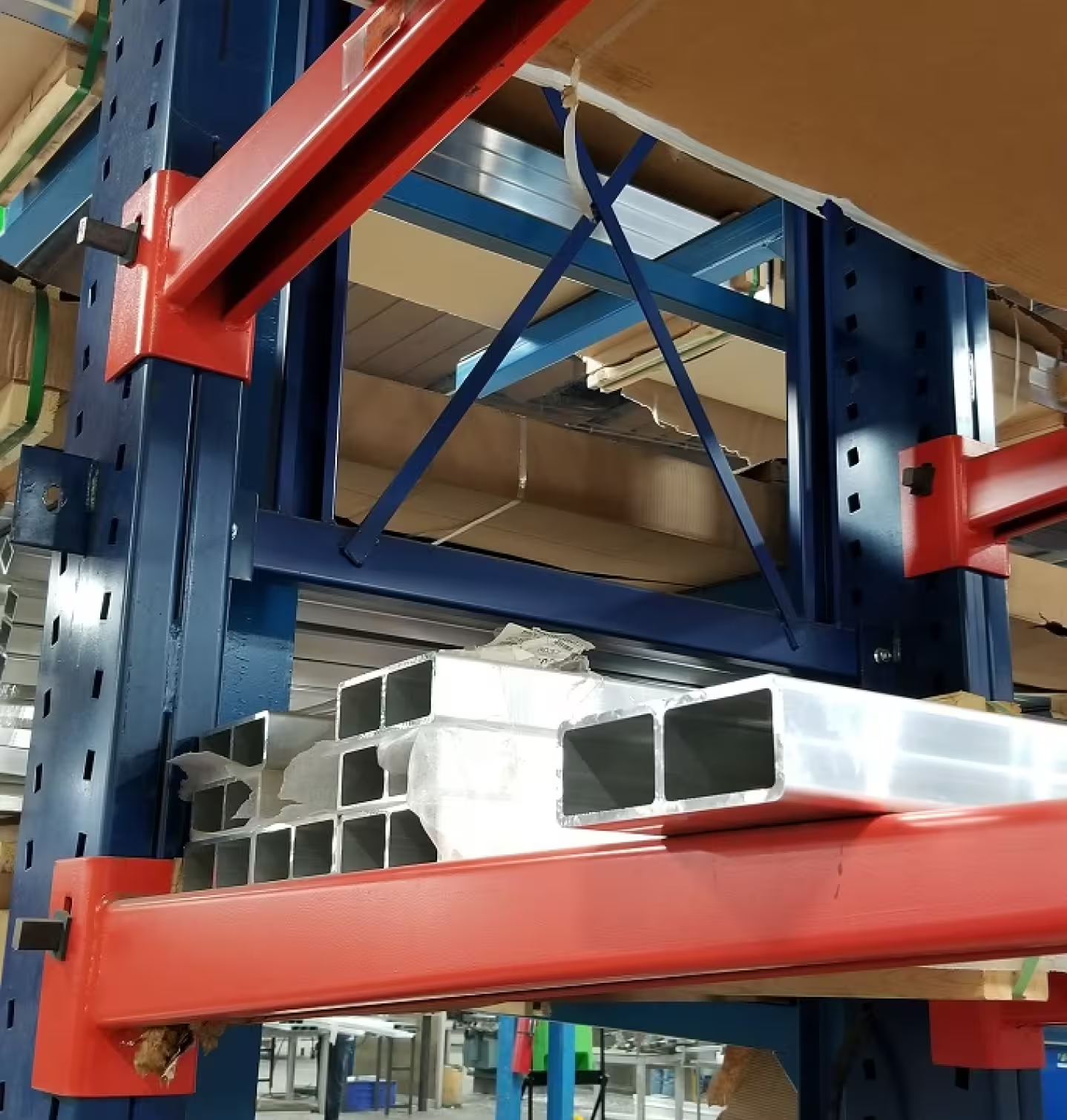

Cantilever Pipe Racks & Steel Storage

Cantilever pipe racks and steel cantilever rack systems are designed to store pipe, tubing, conduit, steel bars, and structural profiles that require stable, evenly distributed support along their length. The open-arm configuration allows materials to be loaded and retrieved without rolling or interference from front uprights.

Arm spacing and load ratings are engineered to prevent sagging, point loading, or uneven stress, which is especially important when handling long metal products or bundled steel. Properly designed cantilever pipe racks improve handling safety while maintaining clear visual access to inventory.

We commonly design these systems for facilities such as:

- Metal service centers

- Manufacturing plants

- Industrial distribution warehouses

where load stability, handling precision, and operator safety are critical.

Cantilever Racking vs Other

Warehouse Racking Systems:

Why and When to Choose Each

|

|

|

Buyer question | Cantilever Racking | Selective Pallet Racking | Drive-In Racking |

|---|---|---|---|

| Best for long materials? | Yes | No | No |

| Handles irregular loads? | Excellent | Limited | No |

| Requires pallets? | No | Yes | Yes |

| Open access to materials? | Yes | Partial | No |

| Best for lumber or pipe? | Yes | No | No |

| Easily expandable? | Yes | Yes | No |

Cantilever Racking

Buyer Questions

| Best for long materials? | Yes |

| Handles irregular loads? | Excellent |

| Requires pallets? | No |

| Open access to materials? | Yes |

| Best for lumber or pipe? | Yes |

| Easily expandable? | Yes |

Selective Pallet Racking

Buyer Questions

| Best for long materials? | No |

| Handles irregular loads? | Limited |

| Requires pallets? | Yes |

| Open access to materials? | Partial |

| Best for lumber or pipe? | No |

| Easily expandable? | Yes |

Drive-In Racking

Buyer Questions

| Best for long materials? | No |

| Handles irregular loads? | No |

| Requires pallets? | Yes |

| Open access to materials? | No |

| Best for lumber or pipe? | No |

| Easily expandable? | No |

Why Selective Pallet Racking Is the

Default Choice for Most Warehouses

In many of the warehouse projects we work on, cantilever racking becomes the most practical solution as soon as materials no longer fit standard palletized storage. Not because it is more complex, but because it directly addresses the real handling and access challenges associated with long and bulky materials.

From our experience, operations storing lumber, pipe, steel, or oversized materials typically prioritize:

- Unobstructed fron access to handle materials of varying lengths

- Stable load support for uneven or overhanging products

- Flexible handling methods, including forklifts, side loaders, or cranes

- Clear visual acces to inventory for inspection and control

Cantilever racking supports these priorities while remaining adaptable as material sizes or volumes change. Arm heights and spacing can be adjusted, and systems can be expanded without redesigning the entire layout.

Because it balances accessibility, load stability, operational efficiency, and long-term flexibility, cantilever racking is widely considered the baseline storage system for long and bulky materials. In our projects, alternative racking systems are usually evaluated only when material characteristics or space constraints require a different approach.

Why Choose Midwest Warehouse Solutions as Your Cantilever Racking Supplier

Many companies sell cantilever racks. Fewer operate as a true cantilever racking supplier and integrator.

When you work with us, we:

- Enginieer steel cantilever rack systems around actual load.

- Size and space cantilever rack arms correctly.

- Design for OSHA and industry compliance.

- Install and anchor systems safely.

- Support future expansion, relocation, or reconfiguration.

This integrator-led approach is especially critical for heavy duty cantilever racking systems, where improper design can lead to material damage or safety risks.

About Cantilever Racking

Systems FAQ’S

What is cantilever racking used for?

We use cantilever racking to store long, bulky, or irregular materials such as lumber, pipe, tubing, steel profiles, and bundled goods that cannot be stored efficiently on pallets. In our projects, cantilever racking is selected when clear front access and stable load support are more important than pallet density.

When should I choose cantilever racking instead of pallet racking?

We typically recommend cantilever racking when storage requirements are driven by material length, shape, or overhang, rather than pallet count. If materials cannot be accessed without interference from front uprights, cantilever racking is usually the safer and more efficient option.

How much weight can cantilever racking hold?

Load capacity depends entirely on how the system is engineered. When we design cantilever racking systems, we size columns, arms, and anchoring based on actual load weights, material distribution, and handling methods. Heavy-duty cantilever racking systems can support very high loads when designed correctly.

What makes a cantilever racking system “heavy-duty”?

In our designs, a heavy-duty cantilever racking system includes reinforced steel columns, higher-capacity cantilever rack arms, and proper base anchoring. We typically specify heavy-duty systems for dense materials, frequent handling, or outdoor environments.

Is MWS a cantilever racking manufacturer or supplier?

MWS operates as a cantilever racking supplier and integrator, delivering engineered, turn-key cantilever racking solutions designed around specific load requirements, site conditions, and operational constraints.

Rather than simply reselling standard cantilever racking components, we design optimal layouts, perform load assessments, ensure code compliance, and integrate complete sales and installation services to deliver safe, efficient, and scalable cantilever racking systems for each application.

Can cantilever racking be used outdoors in Midwest conditions?

Yes. We regularly design outdoor cantilever racking systems for Midwest facilities. When systems are installed outdoors, we account for weather exposure, anchoring requirements, finishes, and long-term durability to ensure safe performance.

Do cantilever racking systems meet OSHA requirements?

When properly designed and installed, cantilever racking systems meet applicable OSHA and industry safety requirements. In our projects, we ensure load ratings, anchoring, and installation practices align with these standards.

Should I buy new or used cantilever racks?

Used cantilever racks can be an option in certain cases, but we always verify load ratings, compatibility, and structural condition before recommending them. For heavy-duty or safety-critical applications, we typically recommend new, engineered systems.

CLAIM YOUR

FREE

Consultation

Save Time and Money

Request a Custom Cantilever Racking Quote

Whether you need cantilever racks for lumber, cantilever pipe racks, or a heavy duty cantilever racking system, work with a top cantilever racking supplier and integrator that designs systems around your materials, space, and handling equipment.

Speak to a cantilever racking expert

515-635-1555

Save time. We will contact you

Provide your details, and we’ll help you find exactly what you need