WAREHOUSE MEZZANINES

Warehouse Mezzanine Systems from a Top Storage Integrator

Engineered steel mezzanines to maximize warehouse space, storage, and operations

Speak with an expert ![]() 515-635-1555

515-635-1555

Home / Warehouse Mezzanines

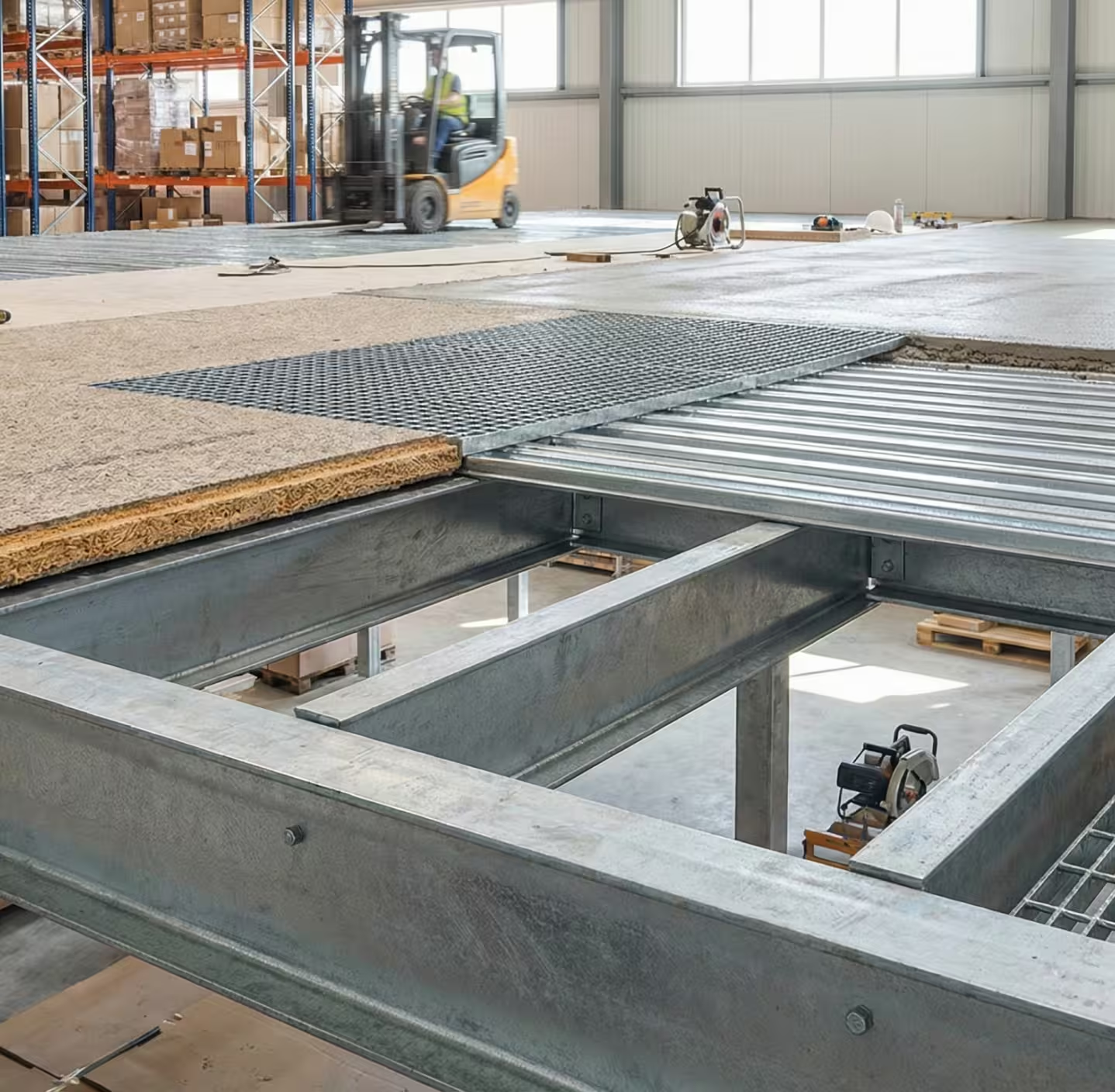

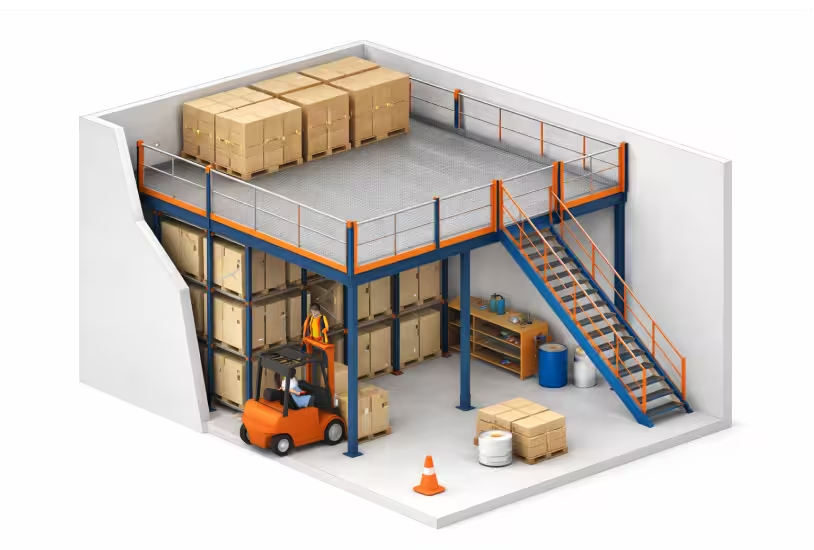

At Midwest Warehouse Solutions (MWS), warehouse mezzanines are one of the most common — and most impactful — systems we design and install. Why? Because most warehouses run out of floor space long before they run out of height.

Warehouse mezzanines are one of the most effective ways to increase usable space inside an existing facility. By converting unused vertical clearance into functional floor area, mezzanine systems allow warehouses to scale storage, picking, and operations without expanding their building footprint.

As a warehouse mezzanine supplier and integrator, we design and install steel mezzanine systems engineered around real load conditions, workflows, and safety requirements. Our mezzanine storage solutions support pallet storage, parts inventory, order fulfillment, offices, and industrial access across manufacturing, distribution, and logistics environments.

Whether you need a warehouse racking mezzanine, pallet rack mezzanine, or full mezzanine floor construction, our systems are designed for long-term performance, compliance, and future growth.

What Is a Warehouse Mezzanine?

A warehouse mezzanine is an elevated steel platform installed inside a warehouse to create additional usable floor space above existing operations. Unlike permanent building expansions, mezzanines are free-standing structural systems that sit within the building envelope. In many cases, they can be expanded, reconfigured, or even relocated as operations evolve.

At MWS, we design mezzanines as complete storage and workspace systems, not just platforms. Depending on the application, a warehouse mezzanine may serve as a mezzanine storage level, a racking-supported structure, or an elevated work and access area integrated into the overall warehouse layout.

From a construction standpoint, mezzanines are built using structural steel columns and beams, with steel mezzanine floors engineered to support specific storage, occupancy, or equipment loads. In some layouts, mezzanines are integrated with warehouse racking systems to maximize vertical space efficiency while maintaining safe access and workflow.

How a Warehouse Mezzanine System Works

A standard warehouse mezzanine system consists of:

- Structural steel columns

- Primary and secondary suport beams

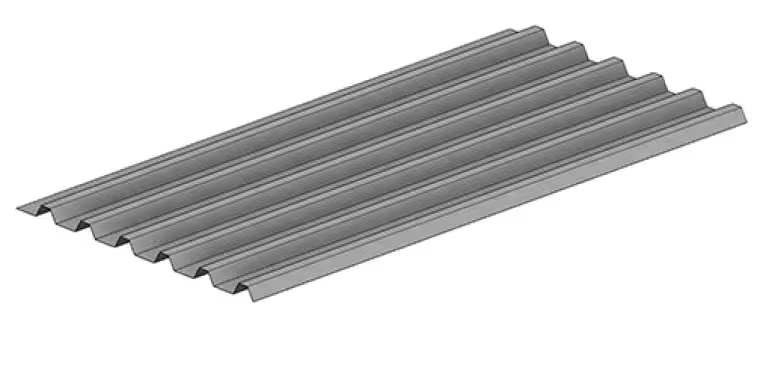

- Load-rated steel mezzanine floor decking

- Metal stairs or platform ladders

- Guard rails and safety railing

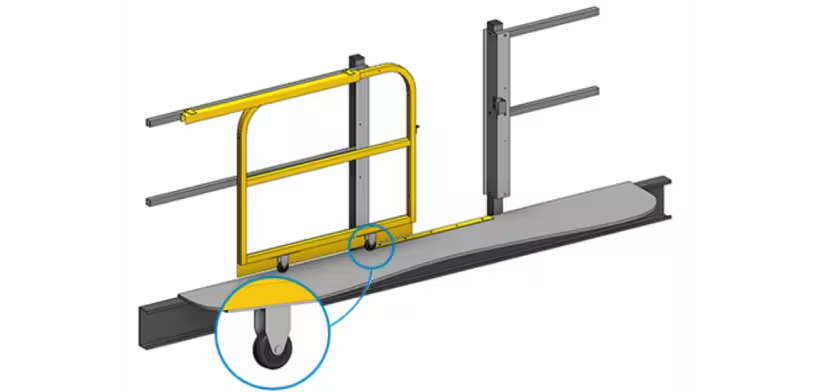

- Self-closing safety gates at pallet drop zones

The mezzanine creates an elevated working or storage surface while preserving open, usable space below for pallet racking, shelving, staging, or production.

When we design mezzanine systems, we always account for:

- Floor load requirements (storage vs occupancy)

- Point loads from racks, shelving, or equipment

- Clear height above and below the mezzanine

- Forklift, pallet jack, or conveyor interaction

- OSHA and building code compliance

- Future expansion or reconfiguration

MEZZANINE FLOOR CONSTRUCTION

Steel Flooring Design

01

How We Engineer the Floor for Real-World Use

At MWS, mezzanine floor construction is not just about building a structure — it’s about designing a floor system that matches how the space will actually be used.

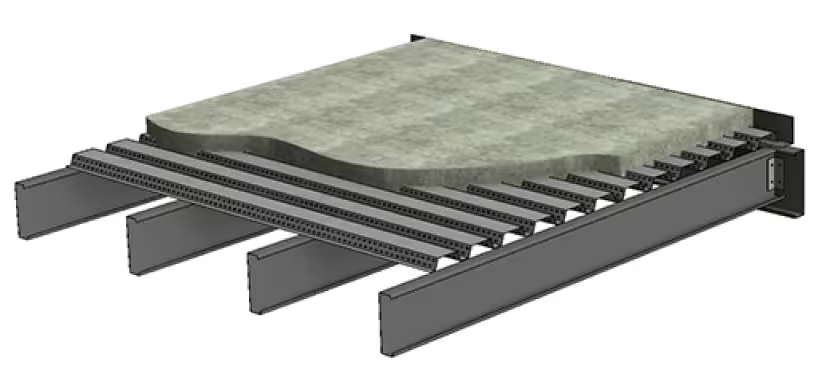

Every mezzanine we design starts with structural steel columns and beams, engineered to support specific load requirements. On top of that structure, we design steel mezzanine floors that are load-rated for storage, employee occupancy, material handling equipment, or mixed-use applications.

Rather than treating flooring as a generic component, we select mezzanine flooring based on design load, usage, and environment.

02

Why Choosing the Right Mezzanine Flooring Matters

At MWS, we’ve seen firsthand that mezzanine flooring decisions have long-term operational consequences. Flooring is not just a surface — it directly impacts how the mezzanine can be used, what equipment can operate on it, and how flexible the space will be over time.

Choosing the wrong mezzanine flooring can:

- Limit usable load capacity

Reducing how the space can be used. - Restrict equipment use

Such as pallet jacks, carts, or roling equipment. - Increase long-term maintenance costs

Especially in demanding environments - Reduce felxibility for future changes

Including layout modifications or load increases

This is why we always treat flooring selection as part of the engineering process, not a finish decision made at the end.

Mezzanine Flooring Options

We Commonly Design & Install

Once load requirements, traffic type, and environmental conditions are defined, we recommend flooring systems that best support long-term performance and safety.

Some of the most common mezzanine flooring options we design and install include:

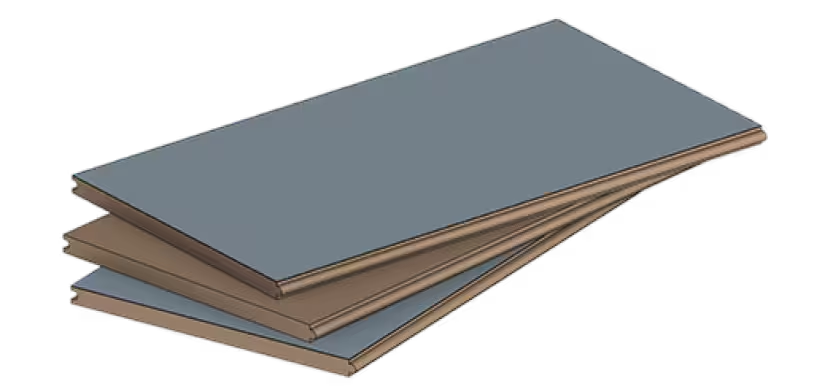

ResinDek® or composite decking

A common choice for storage, shelving, and light material handling. Available unfinished or sealed (gray or custom finishes) depending on environment and durability needs.

Steel B-deck with concrete pour

Often selected when heavier loads, pallet jack traffic, or a more solid floor feel is required. This option provides excellent strength and long-term durability.

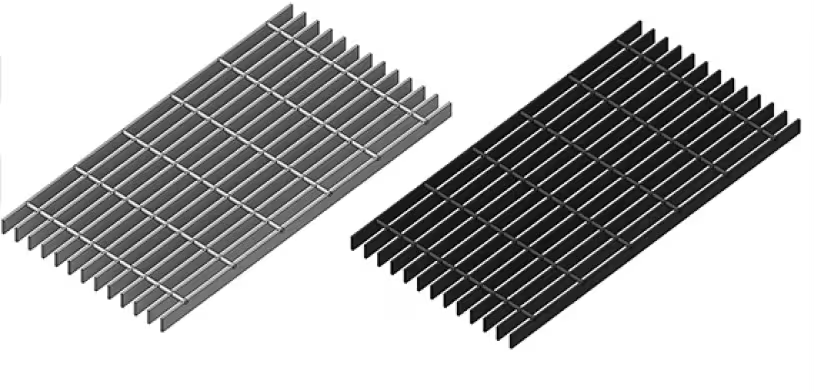

Bar grating or galvanized bar grate

deal for wet or industrial environments where drainage, airflow, or slip resistance is important.

Unfinished deck panels for retail or office environments

Allows customers to apply finished flooring such as carpet, tile, or specialty surfaces to match their space.

Key Features & Benefits

of Mezzanine Systems

At Midwest Warehouse Solutions, most mezzanine projects start with the same conversation:

“We’re out of floor space, but we’re not sure the best way to expand.”

In our experience, when a warehouse has available ceiling height, expanding vertically with a mezzanine system is almost always the smartest first move. It’s faster, more cost-effective, and far less disruptive than expanding the building footprint.

This is why we consistently recommend warehouse mezzanines to our clients.

Why We Suggest Warehouse Mezzanines Systems to our clients:

Vertical space optimization

At MWS, we focus on helping clients take advantage of space they already own. Warehouse mezzanines allow us to convert unused vertical clearance into fully usable floor space without increasing the building footprint.

Structural steel mezzanine construction

We design mezzanine systems using structural steel because it provides the durability, stability, and long-term performance required in industrial environments. These systems are built to last and to adapt as operations change.

Custom load-rated mezzanine floors

Every mezzanine we design is engineered around how it will actually be used. Whether the floor is supporting storage, employees, equipment, or a combination of all three, we size the structure based on real loads, not assumptions.

Integration with warehouse racking

One of the ways we add value is by integrating mezzanines directly with pallet racking, shelving, conveyors, and picking systems. This creates efficient workflows instead of isolated platforms.

Expandable mezzanine systems

We often start clients with a single-level mezzanine and design it so it can become a multi-level mezzanine later. This approach allows growth without forcing a large upfront investment.

A cost-effective alternative to building expansion

In almost every project comparison we do, mezzanines come in at a significantly lower total cost and install much faster than horizontal expansion.

Vertical Expansion vs Horizontal Expansion

Why Mezzanines Win

Expanding a warehouse horizontally often involves major construction, permitting, and operational downtime. By comparison, warehouse mezzanines leverage existing vertical clearance, avoiding many of the costs and complexities associated with building expansion.

From what we see in real projects, horizontal expansion usually involves:

Building Out

usually involves:

- Purchasign or leasing additional land

- New foundations and exterior construction

- Roof, walls, HVAC, and utilities

- Long permitting timelines

- Significant operational disruption

Building Up

By contrast, warehouse mezzanine systems allow us to:

- Use existing building height

- Avoid exterior contruction entirely

- Install while operations continue

- Deliver usable space much faster

For warehouses with adequate ceiling height, mezzanines provide new usable square footage at a fraction of the cost of horizontal expansion.

How Should I Expand

My Warehouse?

At MWS, this is one of the most common questions we’re asked. When a warehouse runs out of space, there are typically three realistic paths forward: expanding the building footprint, relocating to a larger facility, or expanding vertically with a warehouse mezzanine.

|

|

|

Expansion Method | Warehouse Mezzanine | Horizontal Expansion | Facility Relocation |

|---|---|---|---|

| Add usable floor space | Yes | Yes | Yes |

| Uses existing building | Yes | No | No |

| Uses vertical clearance | Yes | No | No |

| Construction complexity | Low | High | Very high |

| Time to deploy | Short | Long | Very long |

| Operational disruption | Minimal | Significant | Severe |

| Cost per square foot | Lower | Higher | Highest |

| Scalability | High | Limited | Fixed |

Single-Sided Cantilever Rack

Feature

| Add usable floor space | Yes |

| Uses existing building | Yes |

| Uses vertical clearance | Yes |

| Construction complexity | Low |

| Time to deploy | Short |

| Operational disruption | Minimal |

| Cost per square foot | Lower |

| Scalability | High |

Horizontal Expansion

Expansion Method

| Add usable floor space | Yes |

| Uses existing building | No |

| Uses vertical clearance | No |

| Construction complexity | High |

| Time to deploy | Long |

| Operational disruption | Significant |

| Cost per square foot | Higher |

| Scalability | Limited |

Facility Relocation

Expansion Method

| Add usable floor space | Yes |

| Uses existing building | No |

| Uses vertical clearance | No |

| Construction complexity | Very High |

| Time to deploy | Very Long |

| Operational disruption | Severe |

| Cost per square foot | Highest |

| Scalability | Fixed |

In most cases where ceiling height is available, mezzanines are the most efficient first expansion strategy

Types of Warehouse Mezzanines

(Use-Case Driven)

Single-Level Mezzanine

One elevated floor for storage, parts, or offices

Multi-Level Mezzanine

Two or more levels for maximum vertical utilization

Online Distribution Center Mezzanine

Multi-level picking and fulfillment

Industrial Catwalk Mezzanine

Access and maintenance walkways

Retail Storage Mezzanine

Backstock above receiving or sales areas

Parts Inventory Mezzanine

Shelving and bins for SKUs and spare parts

How We Approach Scalable Growth with

Single-Level vs

Multi-Level Mezzanines

Another reason we like mezzanine systems is flexibility. Many of our clients start with:

Many of our clients start with:

- A single-level mezzanine to solve immediate space constraint

Then later expand to:

- A multi-level mezzanine as inventory volume, picking activity, or staffing increases

By planning for this from the start, we help clients scale vertically over time instead of committing to a large, permanent construction project upfront

Key Mezzanine Design

& Configuration Options

How We Help Clients Choose the Right Mezzanine System

Once a warehouse mezzanine has been identified as the right expansion strategy, the next question we help clients answer is how that mezzanine should be designed and configured.

At MWS, we don’t treat mezzanines as one-size-fits-all systems. Structural design, access methods, and flooring all play a role in how the mezzanine performs, how safely it operates, and how easily it can adapt as needs change.

Structural Steel vs

Rack-Supported Mezzanine Systems

|

|

Structure Type | Structural Steel Mezzanine | Rack-Supported Mezzanine |

|---|---|---|

| Primary support | Steel columns & beams | Pallet racking uprights |

| Load capacity | Very high | Moderate to high |

| Layout flexibility | Excellent | Limited |

| Space below | Open | Defined by rack aisles |

| Best for | Offices, picking, mixed-use | High-density pallet storage |

| Expandability | High | Moderate |

Structural Steel Mezzanine

Structure Type

| Primary support | Steel columns & beams |

| Load capacity | Very high |

| Layout flexibility | Excellent |

| Space below | Open |

| Best for | Offices, picking, mixed-use |

| Expandability | High |

Rack-Supported Mezzanine

Structure Type

| Primary support | Pallet racking uprights |

| Load capacity | Moderate to high |

| Layout flexibility | Limited |

| Space below | Defined by rack aisles |

| Best for | High-density pallet storage |

| Expandability | Moderate |

Mezzanine Flooring Options (overview)

| Flooring Type | Best For | Equipment Compatibility |

|---|---|---|

| ResinDek® / Composite | Shelving, cartons | Light carts |

| B-deck + concrete | Heavy loads | Pallet jacks |

| Bar grating | Industrial environments | Limited |

| Unfinished deck | Offices / retail | Foot traffic |

Flooring Type

ResinDek® / Composite

Best for:

Shelving, cartons

Equipment compatibility:

Light carts

Best for:

Heavy loads

Equipment compatibility:

Pallet jacks

Bar grating

Best for:

Industrial environments

Equipment compatibility:

Limited

Best for:

Offices / retail

Equipment compatibility:

Foot traffic

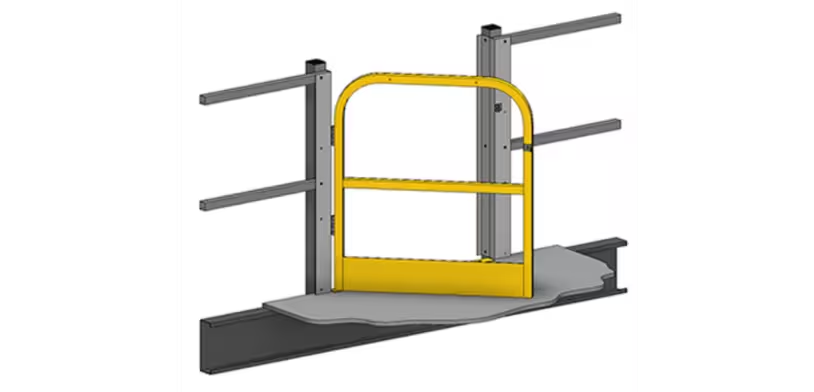

Mezzanine Safety Equipment & Access Components

Every mezzanine we design includes integrated safety systems:

- Guard rails and safety railing

- Self-closing safety gates

- Metal stairs or ladders

- Ladder safety systems

All components are engineered to meet OSHA and building code requirements.

Selecting the Right

Mezzanine Safety Gate

Based on opening size, throughput, and workflow

Mezzanine safety gates are one of the most researched and engineered components of a mezzanine system. At MWS, we select safety gates based on how the opening is used, how often pallets are transferred, and how personnel interact with the drop zone.

In most applications, safety gates fall into one of three functional categories:

Pivot-style safety gates

The most commonly used option, especially for higher-throughput pallet loading areas. Pivot gates are typically available in widths ranging from approximately 5 to 13 feet and are designed to maintain fall protection whether the gate is in the open or closed position.

Single-swing safety gates

Often used in lower-throughput areas or where space constraints limit pivot gate installation. These gates require additional attention to opening direction and worker positioning.

Sliding safety gates

Typically specified for tight layouts or specialty applications. Sliding gates may require additional fall protection measures, such as davit posts or tie-off systems, depending on the design.

Rather than defaulting to a single gate type, we engineer safety gate selection as part of the overall mezzanine design to ensure safe pallet handling, efficient workflow, and long-term compliance.

Why Choose Midwest Warehouse Solutions as Your Warehouse Mezzanine Supplier

Many companies sell mezzanine components. Fewer operate as a true warehouse mezzanine supplier and integrator.

As a warehouse mezzanine integrator, Midwest Warehouse Solutions provides:

- Manufacturer-engineered steel mezzanine systems

Designed and sized for real storage, occupancy, and equipment loads. - Expertise across structural and rack-supported mezzanine systems

Including single-level and multi-level mezzanines for storage, picking, offices, and industrial access. - End-to-end mezzanine services

In-house warehouse consulting, layout design, mezzaine engineering, flooring selection, safety integration, installation, and future reconfiguration. - OSHA and building-code-compliant designs

With integrated guard rails, safety gates, access stairs or ladders and load-rated flooring systems. - long-term support across the Midwest and United States

Including expansion planning, modifications, inspections, and ongoing system optimization.

Frequently Asked Questions About Warehouse Mezzanine Systems

Are warehouse mezzanines cheaper than expanding a building?

In most cases, yes. At MWS, we typically find that warehouse mezzanines provide new usable floor space at a significantly lower cost per square foot than horizontal building expansion. Mezzanines reuse the existing building, slab, and utilities, which eliminates many of the largest cost drivers associated with construction.

How much weight can a warehouse mezzanine support?

Mezzanine load capacity depends entirely on how the system is engineered. We design mezzanine floors based on actual storage loads, occupancy requirements, and equipment use. Steel mezzanine systems can support very high loads when properly designed for the application.

What is the difference between a structural mezzanine and a rack-supported mezzanine?

A structural mezzanine is supported by steel columns and beams and offers maximum flexibility for layout, access, and future expansion. A rack-supported mezzanine uses pallet racking as the support structure and is typically selected for high-density pallet storage where layout flexibility is less critical.

Can pallet jacks or carts be used on a mezzanine?

Yes, but only if the mezzanine floor is designed for it. At MWS, we account for pallet jack traffic during mezzanine floor construction and select flooring systems, such as steel B-deck with concrete, that can safely support rolling equipment and point loads.

What flooring options are available for warehouse mezzanines?

Common mezzanine flooring options include composite decking (such as ResinDek®), steel B-deck with concrete pour, bar grating for industrial environments, and unfinished deck panels for retail or office spaces. The right flooring depends on load requirements, traffic type, and environment.

Can a mezzanine be expanded or modified later?

Yes. When designed correctly, mezzanine systems can often be expanded vertically or reconfigured as operational needs change. Many of our clients start with a single-level mezzanine and later expand into a multi-level system.

Do mezzanine systems require permits and code compliance?

In most cases, yes. Warehouse mezzanines typically require permits and must comply with OSHA and applicable building codes. At MWS, we design mezzanine systems with compliance in mind and support the permitting process.

What safety components are required on a mezzanine?

Mezzanine safety components typically include guard rails, safety railing, self-closing safety gates at pallet drop zones, and approved access methods such as stairs or ladders. Safety systems are designed as part of the mezzanine, not added later.

How long does it take to install a warehouse mezzanine?

Installation timelines vary based on size and complexity, but mezzanines generally install much faster than building expansions. Because they are installed inside the existing building, many mezzanine projects can be completed with minimal operational disruption.

How do I know if a mezzanine is the right solution for my warehouse?

If your warehouse has unused vertical clearance and floor space is constrained, a mezzanine is often the most efficient first expansion strategy. At MWS, we evaluate ceiling height, load requirements, workflows, and growth plans to determine whether a mezzanine is the right fit.

CLAIM YOUR

FREE

Consultation

Save Time and Money

Request a Mezzanine Quote

Whether you need a single-level mezzanine, multi-level mezzanine, warehouse racking mezzanine, or full mezzanine floor construction, work with a team that designs systems around your space, loads, and growth plans.

Speak to a warehouse mezzanine expert

515-635-1555

Save time. We will contact you

Provide your details, and we’ll help you find exactly what you need